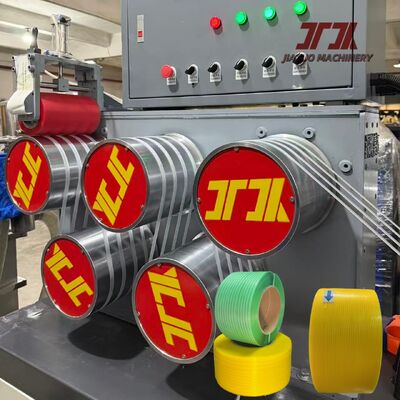

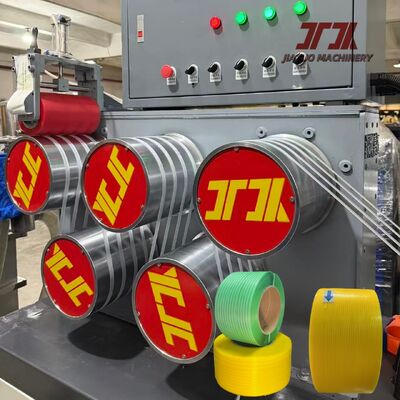

230-260Kg/h Pp 4 Strap Output Production Line Extrusion Machine 220-300m/min Line Speed

PP Strapping Band Production Line: High-Efficiency, Cost-Saving Solution for Packaging Industry

As a professional manufacturer of PP PET strapping band production lines, we specialize in providing integrated production solutions for polypropylene (PP) strapping materials.

Our PP strap production line offers customized width and thickness. It is compatible with 100% recycled materials for cost reduction and profit improvement, and fits various manual tabletop and large automatic strapping machines.

Next, let us introduce Jiatuo's PP strapping production line.

Technical Parameters of PP 2straps output production machine

| 1 |

Materials |

Polypropylene PP raw material pellets, recycled pellets. |

| 2 |

Product |

PP strap (1 mould for 4straps) |

| 3 |

Capacity |

230-260kg/h |

| 4 |

Total install power |

100kw, (actual power consumption is 40-50%) |

| 5 |

Strap width |

5mm-19 mm |

| 6 |

Thickness |

0.4 mm-1.2 mm |

| 7 |

Manpower |

2person/shift |

| 8 |

Workshop required |

L (35m) ×W (2m) ×H (4m) |

| 9 |

Power source |

380V, 50Hz, 3Phase (according to customer requirement) |

| 10 |

Electric components |

Schneider |

| 11 |

Inverter |

INVT |

| 12 |

Switches |

Fotek |

| 13 |

Motor |

GUGAO |

Core Advantages of JIATUO PP strap making machine

1. High Production Efficiency & Stable Performance

Equipped with advanced frequency conversion control systems and precision extrusion machines, the production line achieves a high output of 50-200kg/h (customizable according to requirements). The optimized mechanical structure ensures stable operation with low failure rates, reducing downtime and improving overall production efficiency. All key components are made of high-quality stainless steel and alloy materials, ensuring long service life and low maintenance costs.

2. Superior Product Quality

Adopting precise temperature control technology and multi-stage stretching processes, the produced PP strapping bands feature high tensile strength, good flexibility, and excellent impact resistance. They are not easy to break or deform, ensuring reliable packaging for heavy goods. The line supports uniform coloring and clear printing, with customizable patterns and logos to meet brand promotion needs.

3. Energy-Saving & Cost-Effective

The production line integrates energy-saving motors and heat recovery systems, reducing energy consumption by 15-20% compared to traditional equipment. It can use recycled PP granules as raw materials (with appropriate formula adjustment), effectively lowering raw material costs for customers. The automatic control system minimizes manual operation, saving labor costs and avoiding human errors.

4. Flexible Customization & Easy Operation

We provide tailored solutions based on customers' needs for strapping band width (3-25mm), thickness (0.5-2.0mm), and performance (standard, high-strength, lightweight). The intelligent touch screen control panel simplifies operation, with real-time monitoring of production parameters (temperature, speed, tension) and one-click adjustment, enabling workers to master the operation quickly without professional training.

5. Comprehensive Safety Protection

The line is equipped with multiple safety devices, including emergency stop buttons, over-temperature alarms, and overload protection, ensuring the safety of operators and equipment. The closed-type production structure prevents dust and noise pollution, complying with global environmental and safety standards.

Application of PP strapping

Application: This machine can be used to meet the needs of cartons, tobacco, clothing, paper, electronics, wooden boxes, fruit, electrical (such as refrigerators, washing machines, color TV), food and other industries.This unit has the structure to be compact,the ease of operation ,the output are big, automatic higher merit.

Why choose us

1. The final straps can be packed automatically

2. We major in Strap Production Line for 30years

3. Always have sample machine in our workshop

4. Can take customers to see the running machines

5. Can test the machine for customers

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews