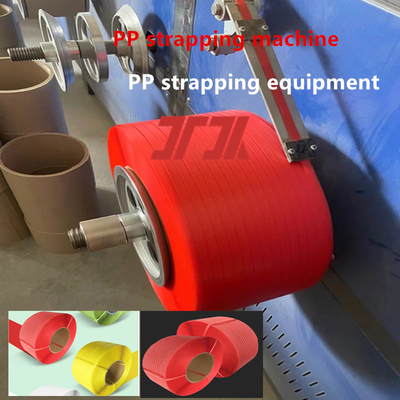

Packaging machinery 100% PP polypropylene strapping production line PP strapping extrusion machine

Line speed up to 300 m/min

Introduction of PP strapping production line:

This is a PP polypropylene belt making machine &PP packaging belt extruder, can produce 5-19mm wide PP packaging belt, advanced technology, first-class technology, the current equipment in the packaging belt industry to hold the first place, the production of PP packaging belt has ultra-thin, lighter, meter length and other advantages, suitable for any automatic baler use.

The company has experienced technical management team, sales team, R & D team, after-sales team, production team, etc., we continue to develop and improve, so that the production of products wider scope of application, better quality, more stable operation.

Technical Parameters of PP strap production line

| Item |

Description |

| Product Name |

PP Strap Making Machine |

| Strap Material |

100% PP Recycle Material/New Raw Material |

| Strap Core Type |

Paper/Plastic |

| Strap size |

5-19mm width 0.4-1.2mm thickness |

| Motor |

GUOMAO |

| Strap Tension |

Adjustable |

| Extruder |

2-12straps output |

| Strap Color |

By Customer's Requirement |

| Warranty |

1 Year |

| Strap Thickness |

0.4-1.2mm |

| Trademark |

JiaTuo China |

| Key Focus |

PP Strap Manufacturing Machine, Plastic Strap Manufacture Equipment, Polypropylene Strap Manufacture Equipment ,Automatic winding machine |

Main features:

Raw materials----PP strapping tape production equipment uses PP polypropylene granules, new materials or recycled materials, with low production costs and large demand.

Advanced technology---- PP strapping tape production equipment has been continuously developed, improved, and upgraded, with advanced equipment technology. The PP strapping tape produced has a small error range and high precision, which is well received by customers.

Extruder---- PP strapping tape equipment uses metering extrusion, and the flow channel is uniform, so that each PP tape produced has the same thickness.

Screw---- PP strapping tape equipment uses a special screw for extruder, which has good plasticization, uniform extrusion, wear resistance, and long service life.

ADVANTAGES

1. Flexible Extrusion Technology – Equipped with both twin-screw and single-screw extrusion systems, allowing customization based on production needs.

2. Cost-Efficient Material – Uses 100% recycled material, reducing raw material costs while supporting sustainability.

3. Fully Automated PLC Control – Ensures precise and efficient production with minimal manual intervention.

4. Stable and Uniform Extrusion - Pressure sensors and precision die head design ensure stable plasticization and consistent output.

5. Advanced Drying System – High-performance dehumidifier ensures optimal material dryness, resulting in strapping with high tensile strength and superior impact resistance.

6. Energy saving and environmental protection---Energy saving and environmental protection oven, saving more than 30% of electricity

7. High speed --- High speed operation machine, line speed can reach 300 meters/minute, advance production by more than 40%, and reduce manual operation by 1-2 people.

Application of PP strapping

Packaging and Logistics:

PP strapping is widely used to secure cartons, boxes, and packages, ensuring safe and stable transportation of goods.

Printing and Paper Industry:

It is ideal for bundling paper rolls, newspapers, and magazines, facilitating efficient storage and shipment.

Food and Beverage Industry:

PP strapping effectively secures bottled beverages, canned goods, and other packaged food items, maintaining product integrity during transit.

Agriculture:

It is commonly used for bundling crops, hay bales, and other agricultural products, providing durability and ease of handling.

After sales service

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews