800kg/H Pp Strapping Band 12straps Output Making Machine With High-Performance Extrusion And Precise Die Head

SHENZHEN JIATUO Plastic Machinery Co., Ltd. - 30 Years of Excellence in Strapping Production Equipment

With three decades of dedicated expertise in strapping production equipment, Jiatuo Plastic Machinery has consistently driven innovation to provide customers with highly efficient, stable, and competitive strapping production solutions.

Specification of PP 12straps output making machine

| Item |

Product name |

Detailed parameters |

| 1 |

Materials |

PP polypropylene new material/recycled material |

| 2 |

Product |

PP strap |

| 3 |

Capacity |

600-650kg/h |

| 4 |

Total install power |

200kw, (Operating power 50-55%) |

| 5 |

Strap width |

5mm-19 mm |

| 6 |

Thickness |

0.4 mm-1.2 mm |

| 7 |

Manpower |

1-2person/shift |

| 8 |

Workshop required |

L (50m) ×W (2m) ×H (4m) |

| 9 |

Power source |

380V, 50Hz, 3Phase(according to customer requirement) |

| 10 |

Machine frame |

100*100*2.5 mm(GB quadrate pipe) |

| 11 |

Warranty period |

12 months |

| 12 |

Weight |

19T |

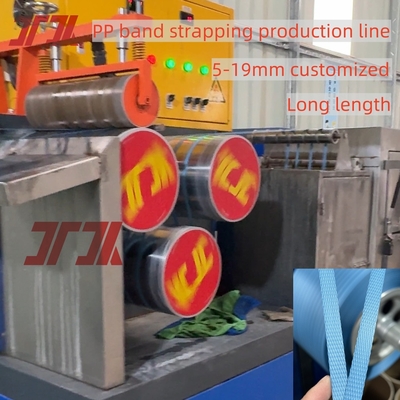

Fully Automatic & Manual PP Strapping Production Line

Fully Automatic & Manual PP Strapping Production Line

This advanced production line is designed for manufacturing both fully automatic and manual PP strapping bands for industrial packaging applications.

Premium Features

1.High-Performance Extrusion

Equipped with 38CrMoAlA alloy extruder barrel, specifically engineered for high-grade strapping production

Integrated hopper-type dehumidifying drying system with auto-loading for consistent material flow

2.Precision Control Systems

Fully(Variable Frequency Drive) motors for optimized energy efficiency

Intelligent temperature control system ensures stable operation

3.Energy Efficiency

Complete frequency conversion system reduces power consumption by up to 30% compared to conventional systems

Applications: Ideal for producing durable strapping for carton bundling, pallet securing, and heavy-duty packaging.

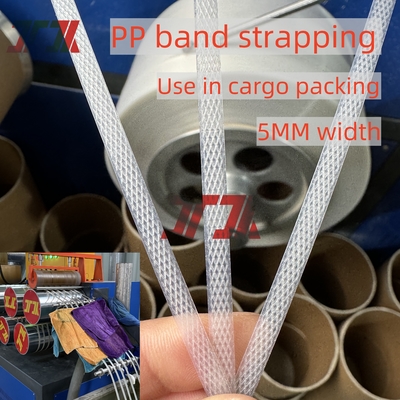

Application of PP strapping belt

Strap PP (polypropylene strapping) is currently the most common used plastic strapping. The later developed Strap PET is of a better quality but this is also noticeable in the price. Strap PP meets the required properties, such as tensile strength, elasticity and tension loss for many applications without failure. Recognition: Polypropylene is often dull and usually has a checkered profile and is available in a few standard colors, black, bleu, white and yellow.

Strap PP is in the longitudinal direction easy to tear, and the specific gravity is lower than that of PET strap. PP strap stays afloat on water.

FAQ

Q: what will you do for the order?

A: Our service likes below:

---------Before order: We will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

------During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers' requirements and provides detail order list and matching manufacturer for reference for customer.

After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer's locale in time when we provide service for client again.

------ After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews