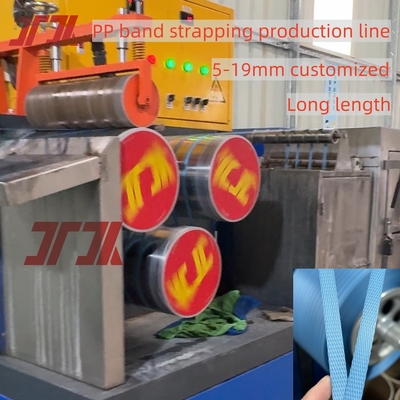

80kw Power PP Strap Making Machine With Good Flexible 50-350kg Tension Strength

Process Flow of PP Packing Strap Production Line

①Material→②Stirring raw material→③Pre crystallization drying→④Extruding→⑤Cooling→⑥Oven preheating→⑦Primary stretching→⑧Secondary stretching→⑨Embossing→⑩Hot forming→⑪Cooling→⑫Winding(finished product)

PP Packing Strap Production Line Details

1. Extruder

--- PP strap making machine can be choose single screw and double screw

--- Special design screw structurer could extrude PP materials smooth, not create excessive shear molecular structure, and ensures the strength of the packing belt.

2. Screen Changer ,Extrusion Mold and Cooling Tank

--- Automatic hydraulic screen changer, non-stop screen changing.

----Waater tank is mad of 304 stainless steel materials.

----The water is heated by water tank heating unit

3. Hual-off Rollers

----Gear transmission

----Chromed rollers

4. Winder

---Winding weight as customer needs

--- Winder could be designed into servo motor unit, inverter motor unit and torque motor according PET or PP materials and with customer's request.

Parameters of PP 1 to 2 production machine:

| 1 |

Materials |

Polypropylene PP raw material pellets, recycled pellets. |

| 2 |

Product |

PP strap (1 mould for 2 straps) |

| 3 |

Capacity |

125-150kg/h |

| 4 |

Total install power |

80kw, (actual power consumption is 40-50%) |

| 5 |

Strap width |

5mm-19 mm |

| 6 |

Thickness |

0.4 mm-1.2 mm |

| 7 |

Manpower |

2person/shift |

| 8 |

Workshop required |

L (28m) ×W (2m) ×H (4m) |

| 9 |

Cooling water |

≤20℃,≥0.3Mpa, 5-8Ton/hr |

| 10 |

Compressed air |

0.5-0.8Mpa |

| 11 |

Power source |

380V, 50Hz, 3Phase (according to customer requirement) |

| 12 |

Electric components |

Schneider |

| 13 |

Inverter |

INVT |

| 14 |

Switches |

Fotek |

| 15 |

Motor power |

Siemens |

| 16 |

Machine frame |

100*100*2.5 mm(GB quadrate pipe)

|

Applications of Final Products of PP Strap Band/Belt Extrusion Line/ PP Strap Band/Belt Extrusion Machine

PP packing strap is widely used in packing applications, it can replaced the steel strap for packing application, as its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

FAQ

Q: Is your company factory or trade company?

A: we are factory, we are engaged in this business for 20 years, we also have our own PET straps factory.

Q: What is the procedure when you buy our machine?

A:Confirm the technology and machine configure -----confirm price----sign contract and make PI---send down payment - start to make machine---inform you before machine finish-you come our factory to check the machine---you accept the machine ----finish payment-exporting---send our technicians to your factory install the machine---answer your question all the using time and supply spare parts with cost only.

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

Q: What is the payment term?

A: The best way for both of us is 30% T/T deposit and 70% T/T balance payment before shipping, since we will test the machine before shipping. Of course, you can choose the way that more convenient (Payment terms: T/T, L/C, Western Union etc.)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews