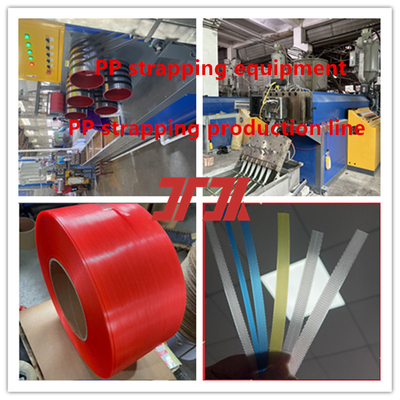

100% Recycle Material PP Packing Belt Machine With PLC Control System And Automatic Winder

Parameter of PP belt double output making machine

| 1 |

Materials |

Polypropylene PP raw material pellets, recycled pellets. |

| 2 |

Product |

PP strap (1 mould for 2 straps) |

| 3 |

Capacity |

125-150kg/h |

| 4 |

Total install power |

80kw, (actual power consumption is 40-50%) |

| 5 |

Strap width |

5mm-19 mm |

| 6 |

Thickness |

0.4 mm-1.2 mm |

| 7 |

Manpower |

2person/shift |

| 8 |

Workshop required |

L (28m) ×W (2m) ×H (4m) |

| 9 |

Cooling water |

≤20℃,≥0.3Mpa, 5-8Ton/hr |

| 10 |

Compressed air |

0.5-0.8Mpa |

| 11 |

Power source |

380V, 50Hz, 3Phase (according to customer requirement) |

| 12 |

Electric components |

Schneider |

| 13 |

Inverter |

INVT |

| 14 |

Switchef |

Fotek |

| 15 |

Motor power |

Siemens |

| 16 |

Machine frame |

100*100*2.5 mm(GB quadrate pipe) |

PP Strap making machine of Application

-

This PP Packing Belt Making Machine can produce different width and thickness pp straps according to the requirement of the clients.

-

It can using the 100% recycled material or mixed the new and recycled material together, which can reduce the product cost and get a good profit.

-

It mainly suitable for pp belts used in light goods

PP double output making machine of Advantages

-

PLC Computer Control System – Stores the last used parameters and supports both Chinese and English interfaces.

-

Excellent Extensibility – Capable of handling demanding specifications (e.g., 50kg tensile strength at 5mm width and 0.45mm thickness).

-

High-Temperature Resistance – Ensures reliable performance under extreme conditions.

-

Energy-Efficient Design – Low power consumption reduces operating costs.

-

Labor-Saving Operation – Only two personnel required for efficient operation.

-

High Production Capacity – One of the most significant advantages for your consideration.

-

Precision Manufacturing – Width and thickness errors exceed industry standard tolerances.

Process flow of PP strap making machine

①Material→②Stirring raw material→③Pre crystallization drying→④Extruding→⑤Cooling→⑥Oven preheating→⑦Primary stretching→⑧Secondary stretching→⑨Embossing→⑩Hot forming→⑪Cooling→⑫Winding(finished product)

Certifications

Welcome to visit us

Our factory address:101A, 1st Floor, Building 20, Second Industrial Zone, Shapuwei Community, Songgang Street, Baoan District, Shenzhen China

FAQ

Q: Why I choose your company?

A: 1.We are one of the leading manufacturers of packing materials and related machinery .

2.Our company has made the PP/PET packing belt making machine 20 years with strong experience and advanced technique

3.Best Quality & Best Service with Competitive price.

4.We have Professional technical team.

Q: How can I make sure the machine running good in my plants?

A: first we will have a instruction of the installing and staff training online,if you need assistance in installing and staff training, we can also send engineers to service oversea and solve all problems.

Q: How long is the guarantee of your machine?

A: 1 year, Main parts is made of high tool steel by special quenching treatment, with high corrosion resistance and wear resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews