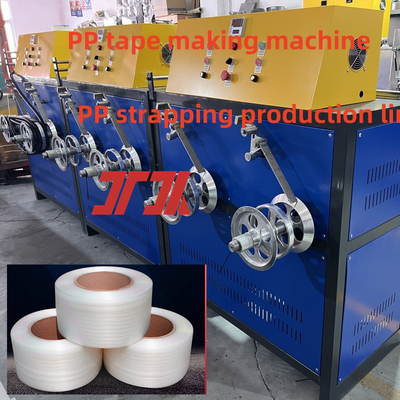

Height 5-15mm Single screw PP strapping machine PP strapping production line for automatic screen changer

Product Description of PP polypropylene extrusion equipment:

Main features of PP strapping production line

High efficiency----high degree of automation, PLC control system, fast production speed, line speed 200-300 m/min.

High quality----high speed rotation, high output, low power consumption, the finished PP straps produced have good toughness and bending resistance, which meet the requirements of fully automatic strapping machines.

Environmental protection----Use PP new materials or recyclable materials for production, non-toxic, odorless and degradable.

Multi-function----Can produce different specifications of width, thickness, length and weight. Width: 5-19mm, thickness: 0.3-1.2mm.

The difference between PP strapping equipment and PET plastic steel strapping equipment:

1. Raw materials used in PP strapping equipment: PP polypropylene drawing grade raw materials, new materials or recycled materials

2. Raw materials used in PET strapping equipment: bottle flakes or crushed materials after mineral water bottles are crushed

| Technical Parameter |

Description |

| Name |

PP Strap Manufacturing Machine |

| Strap Color |

By Customer's Requirement |

| Warranty |

1 Year |

| Motor |

Siemens |

| Power Consumption |

100KW |

| Strap Speed |

>280m/min |

|

Width

|

5-19mm |

|

Thickness

|

0.4-1.2v |

| Power Supply |

380V/220V(customizable) |

| Extruder |

Single Or Double Screw |

| Trademark |

JiaTuo China |

About after-sales:

Our PP strapping equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PP strapping equipment.

2. Analysis of finished product manufacturing costs of PP strapping equipment.

3. Analysis of raw materials used in PP strapping equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PP strapping equipment.

2. Installation, commissioning and training of PP strapping equipment.

3. Repair service of PP strapping equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

8. Training and technical consultation

FQA:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according to the factory length?

A:Yes, we can customize the length according to the customer's factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews