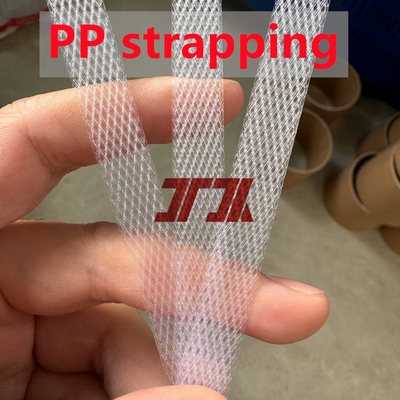

Fully Automatic 300kg/H Plastic PP 4 Straps Strapping Band Production Line With Goood Flexibility

Description of PP PET strapping

PET PP strap is recognized a new environment protective strapping material to substitute for Steel Strap &PP Strap in the ruling international market.

They are not only the aggregation of the intensity and the tenacity of steel strap, but also overcome the disadvantage of the tradition packing material such as insufficient intensity, brittle and so on. At present, they have been applied in wood, steel, and so on.

Our company this line adopt the PLC control the whole line do the automatic production. It use the melting pump and pressure sensor ensure the production stable and strap quality control.

The raw material you can use 100% recycled PET flakes from the waste PET bottles, or virgin material or mixed with each other.

Specification of PP 4 straps output making machine

| Item |

Product name |

Detailed parameters |

| 1 |

Materials |

PP polypropylene new material/recycled material |

| 2 |

Product |

PP strap |

| 3 |

Capacity |

280-300kg/h |

| 4 |

Total install power |

100kw, (Operating power 50-55%) |

| 5 |

Strap width |

5mm-19 mm |

| 6 |

Thickness |

0.4 mm-1.2 mm |

| 7 |

Manpower |

1-2person/shift |

| 8 |

Workshop required |

L (30m) ×W (2m) ×H (4m) |

| 9 |

Power source |

380V, 50Hz, 3Phase |

| 10 |

Electric components |

Schneider |

| 11 |

Inverter |

INVT |

| 12 |

Switches+Thermostat |

Taiwan Fotek |

| 13 |

Motor power |

Gugao |

| 14 |

Solid state relay |

Taiwan Fotek |

| 15 |

Bearing |

FSB |

Advantages of PLC System for PET Strapping Production Line

| Advantage |

Detailed Description |

| High Precision Control |

The PLC system can precisely control various aspects of the production line, such as temperature, speed, and tension, ensuring stable product quality. |

| High Automation Level |

Enables fully automated production, reducing manual intervention, improving efficiency, and lowering labor costs. |

| Strong Flexibility |

PLC programs can be flexibly adjusted according to production needs, adapting to different specifications and materials for strapping production. |

| Easy Fault Diagnosis and Maintenance |

The PLC system features self-diagnostic functions, allowing quick identification of faults, reducing downtime, and improving equipment utilization. |

| High Stability and Reliability |

The PLC system has strong anti-interference capabilities, making it suitable for industrial environments and ensuring long-term stable operation with low failure rates. |

| Data Recording and Analysis |

Can record production data (e.g., output, energy consumption, fault information) in real time, facilitating later analysis and optimization of production processes. |

| Energy Efficiency |

Reduces energy waste and lowers production costs through precise control of heating, cooling, and other processes. |

| User-Friendly Interface |

Equipped with touchscreens or HMIs (Human-Machine Interfaces), making operation simple and intuitive for quick worker onboarding. |

| Remote Monitoring and Management |

Supports remote monitoring, allowing real-time viewing of production line status and enabling remote debugging and maintenance. |

| Strong Scalability |

Functional modules can be expanded according to production needs, meeting future upgrades or modifications of the production line. |

Advantages of PP strap making machine

1-Use 100% recycled material / pellets material / PP crushing material

2-Good drying system to ensure the material equal dry to produce high quality strapping

3-Special design hot forming tensile tank to make good forming, equal width, straight strap.

FAQ

Q: What will you do for the order?

A: Our service likes below:

---------Before order: We will provide relevant information on various technology and business consulted by customers. If clients want to visit our company, we will offer all they need for convenience.

------During order: company designs groundsill installation chart for water, electricity and gas of equipment basing on real condition and customers' requirements and provides detail order list and matching manufacturer for reference for customer.

After equipment arrival, our service personnel will arrive at posted locale for installation, debugging, training and technology transfer till customers can operate independently and manufactures eligible product. Service personnel have to arrive at customer's locale in time when we provide service for client again.

------ After order: we will offer 12months after sales service freely, but our service will be life-long. if some parts are broken, we will send them by express, air or ship as soon as we can

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews