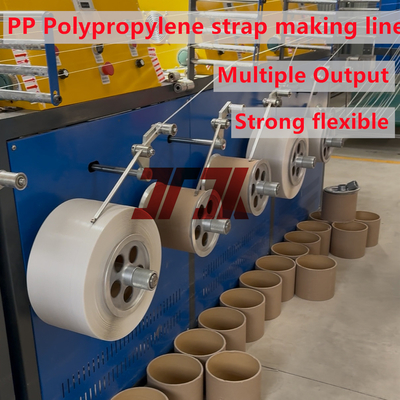

5-19mm Single Double Screw PP Packing Belt Making Line With High Strength And Length

Product Description of PP Packing Belt Making Line

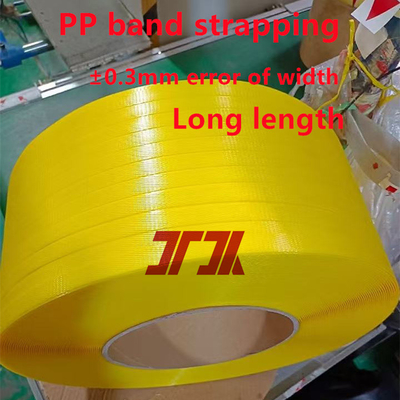

The PP strap production line can produce PP strapping tapes of different colors according to customer requirements, including: red, green, blue, black, yellow, transparent, white, etc.

PP strapping, also known as polypropylene strapping tape, is a strapping tape made of polypropylene brushed resin as the main raw material. It has superior characteristics:

Good plasticity-----can be formed into various shapes and sizes as needed, width: 5-19mm, thickness: 0.3-1.2mm.

Strong breaking tensile force----has a high load-bearing capacity, suitable for various occasions that require packaging and fixing.

Bending resistance----will not easily break or damage even after multiple bending.

Low density----relatively light weight, easy to carry and use.

PP strapping tape is also very easy to use, so it is widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

Technical Parameter of PP belt extrusion line

| Model |

JT-PP90 |

JT-PP110 |

JT-PP125 |

| Productivity |

100-125kg/h |

280-300kg/h |

360-380kg/h |

| Drive Motor |

22kw |

37kw |

55kw |

| Two-station Winder |

260-300m/min,adjustable |

| Strap Size |

Width:5mm-19mm |

Width:5mm-19mm |

Width:5mm-19mm |

| Thickness:0.4mm-1.2mm |

Thickness:0.4mm-1.2mm |

Thickness:0.4mm-1.2mm |

| Installed Capacity |

about40kw |

about 60kw |

about80kw |

| Line Dimension |

26m×2m×2.2m (L×W×H) |

36m×3m×3m (L×W×H) |

40m×5m×3.5m (L×W×H) |

Process flow of PP packing belt production line

Feeding → stirring → pre-drying → melting and measuring extrusion → embryo (belt embryo) cooling and forming

→ oven preheating → primary stretching → secondary stretching → embossening → oven tempering and setting →

cooling → finished product winding

Tips: if you have a choose of printing that you can printing first and then embossing in the project of eight.

General Description of PP strap making line

PP baling tape production line is used to produce mechanical or manual baling tapes made of 100% PP recycled granules or new raw material. This kind of straps are widely used for packing in mining, daily necessities, textile, electrical equipment, instruments, construction, medicine etc. For our machine can product high capacity and length which can saving cost and more profits

Advantages of PP strap making machine

Main features of PP strapping production line

High efficiency----high degree of automation, PLC control system, fast production speed, line speed 200-300 m/min.

High quality----high speed rotation, high output, low power consumption, the finished PP straps produced have good toughness and bending resistance, which meet the requirements of fully automatic strapping machines.

Environmental protection----Use PP new materials or recyclable materials for production, non-toxic, odorless and degradable.

Multi-function----Can produce different specifications of width, thickness, length and weight. Width: 5-19mm, thickness: 0.3-1.2mm.

About After-sales:

1. Pre-sale service

To provide information, market research and forecasting, provide consultancy, offers a variety of convenience and market service and so on.

Pre-sale service's main purpose is to assist the clients prepare the project planning and system requirements analysis, enable our products to maximize meet customer needs, but also to maximize customer investment play the comprehensive economic benefits.

2. After-service

1 Free installation and debugging

2 Provide all kinds of product formula, technology and chemical material manufacturer information

3 According to the customer's requirements, provide technical guidance

4 Technical training for employees of customers

5 Responsible for maintenance service, door to door service if necessary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews