Feature of PP strap production line

1. High Production Capacity

These machines are designed for high-speed production, capable of producing large quantities of PP strapping in a short time.

2. Automated Operation

Modern PP strapping machines are fully automated, reducing the need for manual intervention and ensuring consistent quality.

3. Precision Extrusion

The machines use advanced extrusion technology to produce strapping with uniform thickness, width, and tensile strength.

4. Customizable Width and Thickness

PP strapping machines can be adjusted to produce strapping bands of various widths and thicknesses to meet specific customer requirements.

5. Material Efficiency

These machines are designed to minimize material waste, ensuring efficient use of raw materials and reducing production costs.

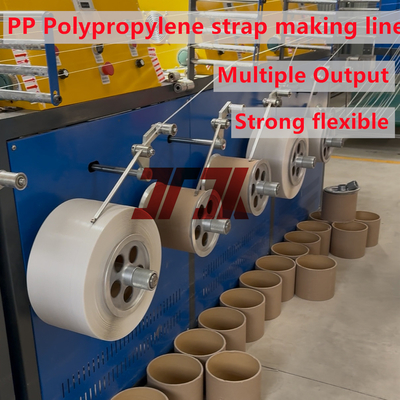

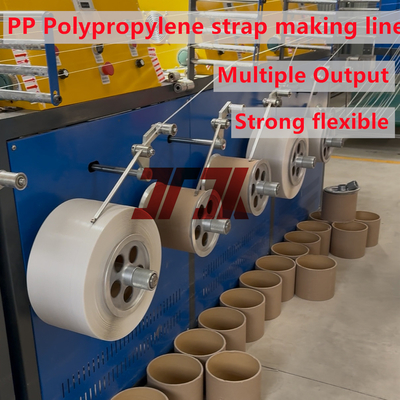

Product Description of PP strap production line

PP (Polypropylene) strapping making machine are specialized equipment designed to produce high-quality PP strapping bands used for bundling and securing loads

JIATUO PP strap making machine has a high production capacity of 5-19mm width and 0.5-1.2mm thickness, and the length of the strips is long enough to achieve cost savings.

Process flow of PP packing belt production line

Feeding → stirring → pre-drying → melting and measuring extrusion → embryo (belt embryo) cooling and forming → oven preheating → primary stretching → secondary stretching → embossening → oven tempering and setting → cooling → finished product winding

Tips: if you have a choose of printing that you can printing first and then embossing in the project of eight.

Applications of PP strap

1. The packing belt used for binding cement brick factory has high tensile strength and high temperature and cold resistance.

2. The packing belt used in aluminum steel strapping factory has high tensile strength, high temperature and cold resistance, and is not easy to break.

3. Chemical fiber packing belt, not easy to break, Packing belt for heavier products,pulling force up to 1000KG.

After Service

1.Free installation and debugging

2.Provide all kinds of product formula, technology and chemical material manufacturer information

3.According to the customer's requirements, provide technical guidance

4.Technical training for employees of customers

5. Responsible for maintenance service, door to door service if necessary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews