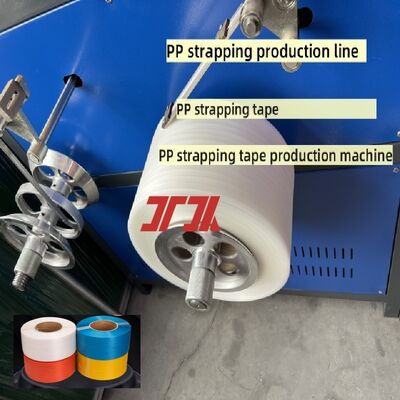

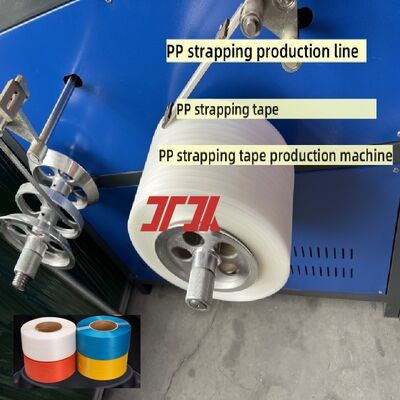

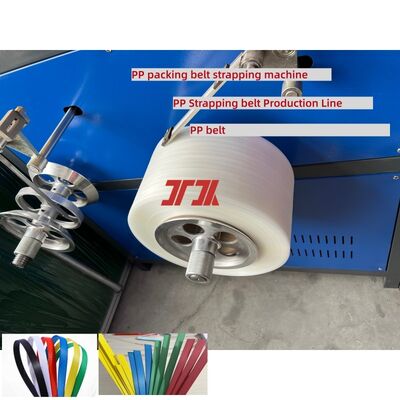

What are the advantages of PP strapping equipment?

## High-Efficiency Production Expert

PP strapping equipment is a highly efficient, fast, and high-capacity extrusion machine. It can continuously produce high-quality PP strapping with amazing efficiency. The line speed is 100-300 m/min. Compared with traditional production methods, it can complete the production of a large number of straps in a shorter time, greatly improving overall production efficiency. With it, even with many orders, you won't be afraid!

## Cost Control Genius

For businesses, cost control is an eternal pursuit. PP strapping equipment excels in this regard. It can precisely control the use of raw materials during the production process, reducing waste. Moreover, the equipment has low energy consumption, which can save businesses a significant amount of money in the long run. Doing more with less money—who wouldn't love that?

## Stable and Reliable Quality

The quality of PP strapping directly affects the packaging effect and transportation safety of goods. The strapping produced by this equipment has very stable quality, with each strap having uniform thickness and strength. Whether for packaging small items or securing large goods, it performs perfectly, ensuring your goods remain securely in transit.

PARAMETER TABLE

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧260-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews