Product Description of pp strapping band making machine:

PP strapping belt, also known as polypropylene strapping belt, is a strapping tape made of polypropylene brushed resin as the main raw material. It has superior characteristics:

Good plasticity-----can be formed into various shapes and sizes as needed, width: 5-19mm, thickness: 0.3-1.2mm.

Strong breaking tensile force----has a high load-bearing capacity, suitable for various occasions that require packaging and fixing.

Bending resistance----will not easily break or damage even after multiple bending.

Low density----relatively light weight, easy to carry and use.

PP strapping belt is also very easy to use, so it is widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

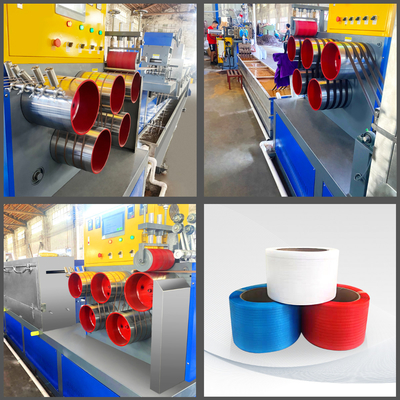

Technical Parameters of pp strapping band making machine:

|

Number of tapes

|

2

|

4 |

6 |

8 |

10 |

12 |

|

Width

|

5-19mm |

5-19mm |

5-19mm |

5-19mm |

5-19mm |

5-19mm |

|

Thickness

|

0.3-1.2mm |

0.3-1.2mm |

0.3-1.2mm |

0.3-1.2mm |

0.3-1.2mm |

0.3-1.2mm |

|

Speed

|

>260 |

>260 |

>260 |

>260 |

>260 |

>260 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

|

Screw

|

90*2800mm |

110*3300mm |

125*3750mm |

135*4050mm |

135*4050mm |

135*4050mm |

|

Capacity /24H

|

2.5-3T |

5-6T |

7-8T |

10-11T |

12-13T |

13-14T |

Feeding and Plasticizing Extrusion:

Polypropylene granules (virgin or recycled) and the necessary masterbatch are fed into the extruder through a hopper.

In the extruder, the material is heated (electrically) and melted by the shearing action of the screw, forming a uniform, viscous fluid.

The molten PP material, propelled by the screw, passes through a specially designed "die" (die head) and is extruded into one or more continuous, thin strips.

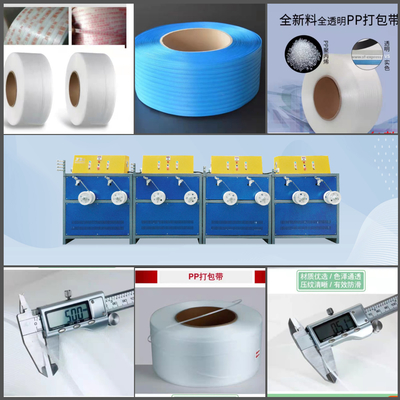

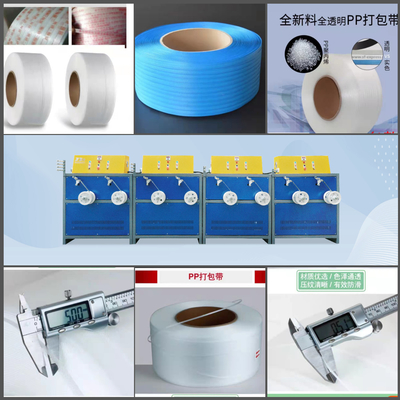

FINISHED PP STRAPPING BELT:

Features:

Good plasticity

Strong breaking force

Bending resistance

Low density

Widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

Packing and Shipping:

Product Packaging:

- The PP Strap Making Machine will be securely packaged in a wooden crate to prevent any damage during transportation.

- All necessary accessories and manuals will be included in the package.

- The package will be labeled with the product name, model number, and shipping address.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews