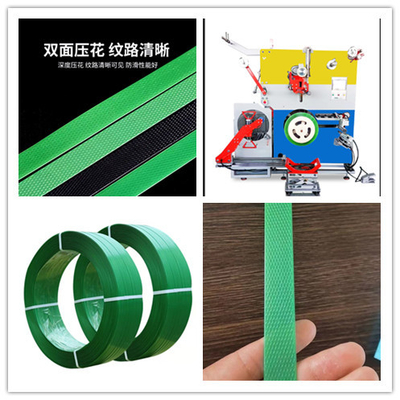

Speed PP Strap Manufacturing Machine with 110*3300mm Double Screw Extruder / Model:JTPP-110

Product Description of strapping band making machine:

The strap tension of this machine is adjustable, which allows users to produce straps with varying levels of tightness. This feature makes the machine versatile and capable of producing different types of straps for different applications.

The Power Supply of the PP Strap Making Machine is customizable, with options for either 380V or 220V. This allows the machine to be used in a variety of settings, including factories and warehouses with different power requirements.

The strap thickness range of the Plastic Strap Manufacture Equipment is between 0.4mm and 1.2mm. This wide range of thicknesses allows users to produce straps that are suitable for a variety of applications.

The PP Strap Making Machine is equipped with a Video Outgoing-Inspection system, which allows users to monitor the production process and ensure that the straps meet the required quality standards. This feature makes the machine highly efficient and helps to reduce waste and errors.

The strap speed of the Plastic Strap Production Machine is impressive, with a minimum speed of 280 meters per minute. This high speed allows users to produce large quantities of straps in a short amount of time, making it ideal for large-scale manufacturing.

In summary, the Polypropylene Strap Production Machine is a reliable and efficient Plastic Strap Manufacture Equipment that is capable of producing high-quality straps for a variety of applications. With adjustable strap tension, customizable power supply, a wide range of strap thicknesses, Video Outgoing-Inspection, and high strap speed, this Plastic Strap Production Machine is an excellent investment for any business looking to streamline its manufacturing process and increase productivity.

Features of strapping band making machine:

- Product Name: PP Strap Making Machine

- Automatic Grade: Fully Automatic

- Video outgoing-inspection: Provided

- Strap Core Type: Paper/Plastic

- Strap Material: PP Recycle Material/New Raw Material

- Warranty: 1 Year

Keywords: PP Strap Manufacturing Machine, Polypropylene Banding Machine, PP Banding Machine Manufacturing Machine

Technical Parameters of strapping band making machine:

Model | JTPP-110 |

| Screw | 110*3300mm |

| Screw Material | 38CrMoALA |

| Trademark | JiaTuo China |

| Strap Material | PP Recycle Material/New Raw Material |

| Warranty | 1 Year |

| Power Consumption | 100KW |

| Strap Core Type | Paper/Plastic |

| Machine Type | Single/Double Screw |

| Key Selling Points | Leading German And Japanese Advanced Technology |

| Plastic Processed | PP |

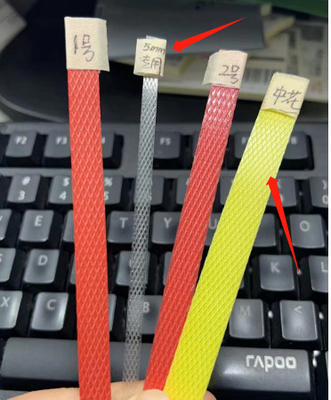

| Strap Color | By Customer's Requirement |

Applications of strapping band making machine:

The PP strap making machine is a perfect fit for several industries that require plastic strap manufacture equipment, including the packaging industry, construction industry, and logistics industry. The machine can produce plastic straps that are used to secure packages for transportation, building materials for construction, and other applications that require packaging and strapping.

The JTPP model of the PP strap making machine is fully automatic, which means it requires minimal human intervention, making it highly efficient and time-saving. The machine comes with a single or double screw extruder, which makes it suitable for different types of plastic materials. It has a power consumption of 100KW, which ensures that the machine is energy-efficient and cost-effective.

The PP strap making machine has a minimum order quantity of 1 set, and the price is negotiable, depending on the order quantity. The packaging details for the machine include plastic film, which ensures that the machine is protected from any external damage during transportation. The delivery time for the machine is 30-40 days, and a video outgoing-inspection is provided with the product.

In conclusion, the PP strap making machine is a highly efficient and reliable plastic strap manufacture equipment that can produce high-quality plastic straps suitable for several applications. The machine can be used in different industries, including the packaging, construction, and logistics industries. The JTPP model of the machine is fully automatic, which ensures that it requires minimal human intervention and is highly efficient. The machine comes with a single or double screw extruder, has a power consumption of 100KW, and is certified with IS CEO, making it a trustworthy product in the market.

Customization of strapping band making machine:

- Brand Name: PP strap making machine

- Model Number: JTPP-110

- Place of Origin: CHINA

- Certification: IS CEO

- Minimum Order Quantity: 1 SET

- Price: Negotiable

- Packaging Details: plastic film

- Delivery Time: 30-40days

- Strap Color: By Customer's Requirement

- Screw Material: 38CrMoALA

- Power Supply: 380V/220V(customizable)

- Strap Tension: Adjustable

- Winder: Double Station Winder

Our product is a Polypropylene Strap Production Machine, also known as a Plastic Strapping Manufacturing Machine or a Polypropylene Banding Machine. We offer customization services to meet the specific needs of our customers. Contact us to learn more.

Support and Services:

The PP Strap Making Machine is a high-performance machine used for producing PP (polypropylene) straps of various sizes and thicknesses. Our machine is designed with advanced technology, ensuring efficient and reliable production of high-quality straps.

We provide technical support and services for our PP Strap Making Machine to ensure that our customers can operate the machine with ease and achieve optimal performance. Our technical support team is available to assist with any technical issues that may arise during the installation, operation, or maintenance of the machine.

We also offer training services for our customers to ensure that they are fully equipped with the necessary knowledge and skills to operate the machine efficiently. Our training sessions cover topics such as machine operation, maintenance, troubleshooting, and safety.

In addition, we provide spare parts for our PP Strap Making Machine to ensure that our customers can quickly and easily replace any worn or damaged parts. Our spare parts are manufactured to the same high standards as the original parts, ensuring optimal performance and longevity of the machine.

Packing and Shipping:

Product Packaging:

- The PP Strap Making Machine will be packed in a wooden case to ensure safe and secure transportation.

- The package dimensions are 2200mm x 1200mm x 1800mm.

- The gross weight of the package is 1500kg.

Shipping:

- The PP Strap Making Machine will be shipped via sea or air freight, depending on the customer's preference and location.

- Shipping costs will be calculated based on the destination and shipping method chosen.

- The estimated delivery time is 30-45 days for sea freight and 5-7 days for air freight.

- Customers will be provided with a tracking number to monitor the status of their shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews