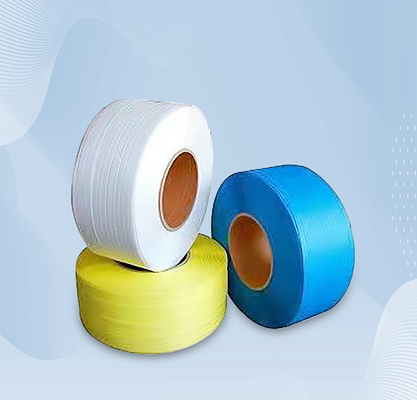

Packaging machinery 5-19mm PP strapping production line PP strapping machine PP strapping production equipment with automatic winding machine and PLC control

Product Description of pp strapping band making machine:

PP strapping tape production equipment is a mechanical equipment used to manufacture polypropylene (PP) strapping tape. It is widely used in the packaging industry and has more advantages:

High degree of automation----PP strapping tape equipment adopts high-speed automation design, PLC control, simple operation and convenient debugging.

High production efficiency----high speed, continuous production, line speed can reach 200-300 m/min.

Stable product quality---Automation control ensures stable product quality, with more than 30 years of experience in manufacturing PP strapping tape equipment.

Energy saving and environmental protection----PP strapping tape equipment adopts energy-saving motors and circulating cooling water systems to reduce energy consumption and pollution.

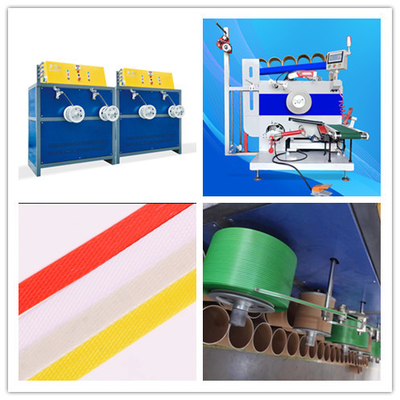

Features of PP tape making machine:

Adopt Siemens motor, high-speed operation, low failure rate.

Adopt extruder special screw, good plasticization, long service life.

Adopt torque motor control, automatic deviation correction system, more integrated winding.

EXTRUSION PARAMETERS TABLE

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

100% PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧200-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

The main components of PP strapping equipment:

Extruder---- core component, heats and melts PP particles and then extrude them into shape.

Die head---- determines the shape and size of the plastic strap.

Cooling system----quickly solidifies the extruded plastic strap through water cooling or air cooling.

Tractor---- pulls out the cooled plastic strap to ensure uniform thickness and width.

Oven---- heats the strap embryo and stretches it into shape, stretching ratio: 10-20 times.

Coiler---- winds the plastic strap into a roll for easy storage and transportation.

Control system---- PLC automatically controls each component to ensure stable production.

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FQA:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according to the factory length?

A:Yes, we can customize the length according to the customer's factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews