Plastic Machinery Single Screw PP Strapping Strapping Production Line PP Strapping Machine PP Strapping Equipment for 100% Recycled Materials

Product Description of pp strapping band making machine:

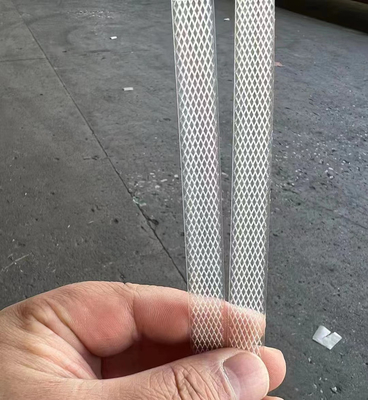

PP strapping tape, also known as polypropylene strapping tape, is a strapping tape made of polypropylene brushed resin as the main raw material. It has superior characteristics:

Good plasticity-----can be formed into various shapes and sizes as needed, width: 5-19mm, thickness: 0.3-1.2mm.

Strong breaking tensile force----has a high load-bearing capacity, suitable for various occasions that require packaging and fixing.

Bending resistance----will not easily break or damage even after multiple bending.

Low density----relatively light weight, easy to carry and use.

PP strapping tape is also very easy to use, so it is widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

About auxiliary raw materials:

PP strapping equipment is equipped with 3 sets of auxiliary feeders,

Dyeing masterbatch can be added to change the color of PP strap

Filling masterbatch can be added to reduce the cost of PP strap

Defoaming agent can be added to eliminate moisture in PP raw materials

Working process of PP strapping equipment:

Raw material preparation----Add PP granules into the extruder hopper.

Extrusion molding----PP granules are melted in the extruder and extruded through the mold.

Cooling and shaping----The extruded strapping tape enters the cooling water tank for cooling and shaping.

Traction and stretching---- The traction machine pulls the strapping tape, and the stretching machine performs stretching treatment.

Embossed treatment---- The embossing machine embosses the surface of the strapping tape.

Shaping oven---- Heat and shape the PP tape again to achieve consistent specifications.

Reeling and packaging----The reeling machine winds the strapping tape into a roll and puts it into storage after packaging.

Features of pp strapping band making machine:

- Product Name: PP Strap Making Machine

- Strap Core Type: Paper/Plastic

- Applicable raw materials:PP polypropylene new material/recycled material(index number: 2.0~3.8 are suitable)

- Screw diameter (mm): 110*3300mm

- Key Selling Points: Leading German And Japanese Advanced Technology

- Polypropylene Strap Manufacture Equipment

- Plastic Strap Production Machine

- Plastic Strapping Manufacturing Machine

Technical Parameters of pp strapping band making machine:

| Technical Parameters |

Value |

| Name |

PP Strap Making Machine |

| Strap Width |

5-19mm |

|

Thickness

|

0.4-1.2mm |

| Strap Speed |

>200-300m/min |

| Automatic Grade |

Fully Automatic |

| Strap Material |

PP Recycle Material/New Raw Material |

| Key Selling Points |

Leading German And Japanese Advanced Technology |

| Screw Material |

38CrMoALA |

| Video outgoing-inspection |

Provided |

| Strap Core Type |

Paper/Plastic |

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is PP strap making machine.

- Q: What is the model number of this product?

A: The model number of this product is JTPP.

- Q: Where is this product manufactured?

A: This product is manufactured in China.

- Q: Does this product have any certification?

A: Yes, this product is certified by IS CEO.

- Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 1 set.

- Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable.

- Q: How is this product packaged?

A: This product is packaged with plastic film.

- Q: How long does it take for delivery?

A: The delivery time for this product is 30-40 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews