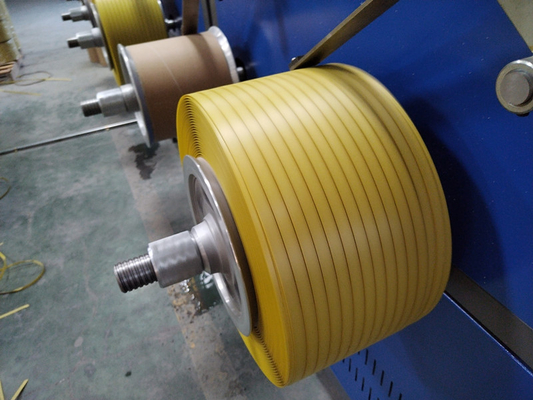

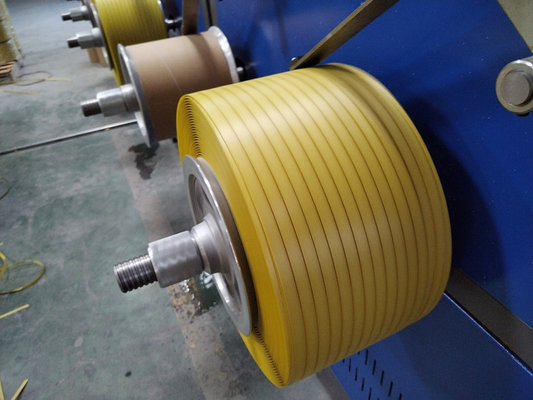

Plastic Machinery Twin-screw Sandwich PP Strapping Tape Production Line PP Strapping Tape Equipment with 5-19mm PP Strapping Machine

PRODUCT DESCRIPTION

PP strapping production line 1 to 4 product parameters:

Name: PP 1 to 4 strapping production line

Model number: JTPP-110

Applicable raw materials: New PP particles, PP recycled materials, PP crushed materials

Number of screws: 1 Screw

Number of extruded belts: 4

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200-600kg/h

Installation size: L38*W2.0*H4.0(m)

| Model No. |

Screw Size |

No. of strap |

Capacity |

Total Power |

Width |

Thickness |

Installation Dimensions |

| JTPP-90 |

2800mm |

2 |

100kg/h |

80kw |

5-19mm |

0.4-1.2mm |

30*2.0*4.0M |

| JTPP-100 |

2800mm |

3 |

150kg/h |

90kw |

5-19mm |

0.4-1.2mm |

30*2.2*4.0M |

| JTPP-110 |

3300mm |

4 |

200kg/h |

100kw |

5-19mm |

0.4-1.2mm |

38*2.0*4.0M |

| JTPP-120 |

3700mm |

6 |

300kg/h |

120kw |

5-19mm |

0.4-1.2mm |

40*2.0*4.0M |

Advantage of our machine

- PP raw materials do not need to separate the dry and water treatment . There are automatic circulation on preheating and

drying that save a large number of equipment investment and reduce the production cost by 30%;

The screw can be single screw or twin screw extruder

-

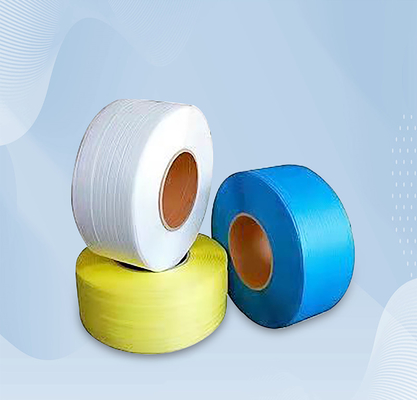

The PP strapping tape production line can produce PP strapping tapes of different colors according to customer requirements, including: red, green, blue, black, yellow, transparent, white, etc.

The PP strapping tape production line can use twin-screw extrusion or single-screw extrusion according to customer requirements, and can produce all-plastic PP tapes or sandwich PP tapes.

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service.

Q2:When can I get my machine after I paid?

A2:We will deliver the machines on time as the date we agreed both side.

Q3:How can I install my machine when it arrives?

A3:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q4:What's your guarantee or the warranty of the quality if we buy your machines?

A4:We offer you high quality machines with 1 years guarantee . we will give u spare part free in 1 years.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews