Customizable Power Supply 380V/50HZ PP Strap Making Machine for5-19mm Width Single screw extrusion equipment

Product Description of PP polypropylene extrusion equipment:

This is a PP polypropylene belt making machine &PP packaging belt extruder, can produce 5-19mm wide PP packaging belt, advanced technology, first-class technology, the current equipment in the packaging belt industry to hold the first place, the production of PP packaging belt has ultra-thin, lighter, meter length and other advantages, suitable for any automatic baler use.

Working process of PP strapping equipment:

Raw material preparation----Add PP granules into the extruder hopper.

Extrusion molding----PP granules are melted in the extruder and extruded through the mold.

Cooling and shaping----The extruded strapping tape enters the cooling water tank for cooling and shaping.

Traction and stretching---- The traction machine pulls the strapping tape, and the stretching machine performs stretching treatment.

Embossed treatment---- The embossing machine embosses the surface of the strapping tape.

Shaping oven---- Heat and shape the PP tape again to achieve consistent specifications.

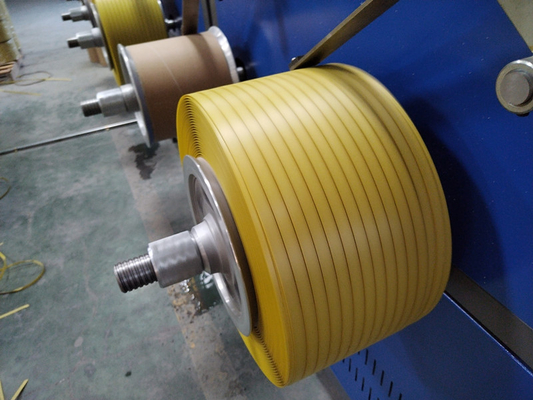

Reeling and packaging----The reeling machine winds the strapping tape into a roll and puts it into storage after packaging.

Features of PP polypropylene extrusion equipment:

- Product Name: PP Strap Making Machine

- Strap Core Type: Paper/Plastic

- Screw diameter (mm): 110*3300mm

- Raw material:PP polypropylene new material/recycled material

- Paper core diameter:Ø200*180mm

- Key Selling Points: Leading German And Japanese Advanced Technology

- Video outgoing-inspection: Provided

- Strap Tension: Adjustable

ABOUT US:

The company has experienced technical management team, sales team, R & D team, after-sales team, production team, etc., we continue to develop and improve, so that the production of products wider scope of application, better quality, more stable operation.

- Leading German and Japanese advanced technology - ensures high-quality and efficient production

- Siemens motor - provides stable and reliable power supply

- High-grade screw material (38CrMoALA) - ensures durability and longevity of the machine

- Flexible production options - can produce PP straps of different widths, thicknesses, and colors

- Easy to operate and maintain - reduces labor and maintenance costs

Our PP strapping equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PP strapping equipment.

2. Analysis of finished product manufacturing costs of PP strapping equipment.

3. Analysis of raw materials used in PP strapping equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PP strapping equipment.

2. Installation, commissioning and training of PP strapping equipment.

3. Repair service of PP strapping equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FQA:

Q: What are the specifications that the PP strapping production line can produce?

A: Width: 5-19mm, thickness: 0.3-1.2mm.

Q: What's the price of this machine please?

A: We have different extrusion capacities and different models, and the corresponding prices are also different.

Q:Can the length of the PP strapping production line be customized?

A: YES

Q:What is the transaction method of PP strapping production line?

EXW ,FOB,CIF

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews