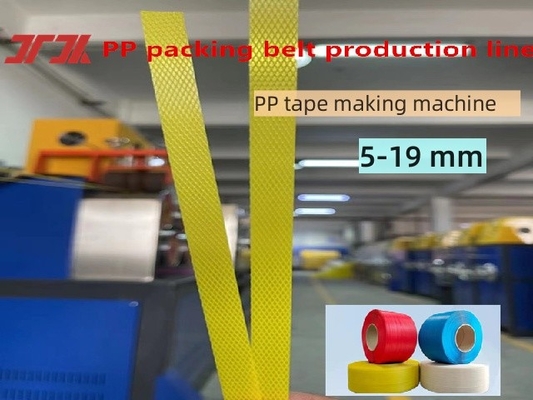

High speed 5-15mm double layer sandwich PP strapping tape production line PP strapping machine for automatic winding machine

Product Description of pp strap manufacturing machine:

PP packaging belt equipment is a kind of machine specially used for the production of PP polypropylene packaging belt, with the rapid development of logistics and packaging industry, PP packaging belt because of its excellent tensile strength, wear resistance and water resistance, gradually replace the traditional metal packaging belt, widely used in all walks of life in the market. PP packing tape equipment through a series of processes, PP particles into high quality packing tape, widely used in a variety of cartons, wooden boxes, pallets and other items packaging fixed.

The working principle of PP packing equipment mainly includes the following steps:

1. Raw material preparation---- The use of high-quality PP particles/recycled materials as raw materials to ensure that the produced packaging tape has good physical properties.

2. Melt extrusion---- PP particles into the extruder, after high temperature heating and melting, forming a continuous PP melt.

3. Molding cooling----- The melted raw material is extruded through the mold to form a specific width with the embryo, and is cooled immediately to maintain the shape.

4. Tensile shaping----- stretch the cooled belt through the stretching machine to increase its strength and tensile properties.

5. Oven shaping-----the stretched packaging belt enters the oven again, heating and shaping, making the product more accurate.

6. Winding of the finished product------ winding the stretched packing tape according to the preset length, and packaging, convenient storage and transportation.

Features of pp strap manufacturing machine:

PP packing belt, also known as polypropylene packing belt, is a packing belt made of polypropylene wire-drawn resin as the main raw material. It offers a range of superior properties:

1. Good plasticity, which means it can be molded into various shapes and sizes as needed.

2. Strong breaking tension, which makes it have a high load-bearing capacity, suitable for a variety of occasions that need to be packaged and fixed.

3. Resistance to bending, even after multiple bending, it will not easily break or damage.

4. Low density, which makes it relatively light and easy to handle and use.

5. Good tensile impact performance, can maintain a certain stability when impacted.

In addition, PP packaging belts are also very easy to use, so they have been widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

Technical Parameters of pp strap manufacturing machine:

| Parameter |

Value |

|

Model

|

JTPP-110 |

| Screw diameter (mm) |

110*3300mm |

|

PP packing material

|

PP polypropylene new material/recycled material

|

| Video outgoing-inspection |

yes |

| Automatic Grade |

Fully Automatic |

|

PP polypropylene new material/recycled material

|

¢200*180mm |

| Strap Speed |

>260-300m/min |

| Strap Tension |

Adjustable |

|

Equipment layout diagram

|

YES |

| Warranty |

1 Year |

Applications of pp strap manufacturing machine:

We are a professional PP packing belt manufacturer, PP packing belt equipment manufacturer, PP packing belt delivery details are as follows:

Quantity: ≧1 ton (10KG/ roll=100rolls)

Packaging: Paper packaging

Grade: PP polypropylene new material/recycled material

Third party test report : SGS(Can provide)

Tension test report: YES (Can provide)

Color: White, transparent, yellow, red, blue, black (customizable)

Note: We will pack the whole card, and wrap it with PE film, and then fix it with a packing belt, so there is no need to worry about loose during transportation.

Support and Services of pp strap manufacturing machine:

PP Strap Making Machine Technical Support and Services

We offer comprehensive technical support and services for our PP Strap Making Machine to ensure your satisfaction. Our team of experienced technicians is available to provide on-site or remote assistance with troubleshooting and maintenance. We provide a wide range of services to our customers, including:

- Repairs and maintenance

- Installation and setup

- Software updates and upgrades

- Troubleshooting and diagnostics

- Parts replacement and repair

- Training and user support

Our team is committed to helping you get the most out of your PP Strap Making Machine. We are always here to answer any questions you may have and provide assistance with any issue that may arise. We strive to provide our customers with the best customer support and satisfaction.

FAQ:

Q1: What is the brand name of the PP strap making machine?

A1: The brand name of the PP strap making machine is PP strap making machine.

Q2: What is the model number of the PP strap making machine?

A2: The model number of the PP strap making machine is JTPP-110.

Q3: Where is the PP strap making machine made?

A3: The PP strap making machine is made in China.

Q4: What certification does the PP strap making machine have?

A4: The PP strap making machine has IS CEO certification.

Q5: What is the minimum order quantity for the PP strap making machine?

A5: The minimum order quantity for the PP strap making machine is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews