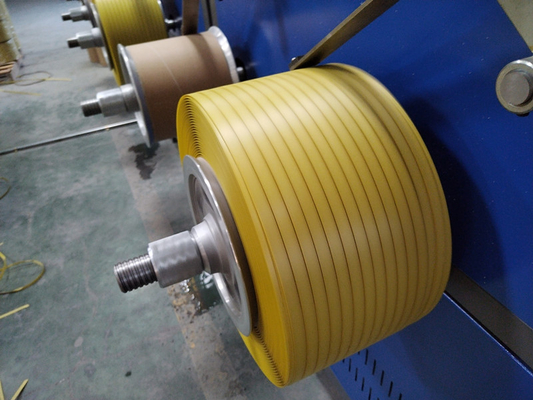

Advanced PP extrusion equipment PP strapping production line PP strapping machine with single screw extruder

Product Description of pp strapping band making machine:

1.PP packaging belt production line features: raw materials can be recycled or mixed new materials to produce packaging belts, can also be appropriate according to customer conditions such as calcium carbonate to reduce production costs,

2.PP packaging belt production line can improve product profits and break through market competitiveness. High output, finished product line speed up to 260m-300/min;

3.PP packing belt production line design is reasonable, beautiful, durable;

4.PP packing belt production line adopts high-precision die parts, so that the width and thickness error range of finished PP packing belt is less than the national acceptance standard;

Features of pp strapping band making machine:

- Product Name: PP Strap Making Machine

- Screw diameter (mm): 110*3300mm

- Power Consumption: 100KW

- Extruder: Single Or Double Screw

- Winder: Double Station Winder

- Plastic Strap Production Machine

- PP Banding Machine Manufacturing Machine

- PP Banding Machine Manufacturing Machine

- pp strapping band making machine

- pp strap production line

- PP strapping band making machine

Technical Parameters of pp strapping band making machine:

| Product Attributes |

Specifications |

| Name |

PP strapping equipment

|

| Power Consumption |

100KW(Power for operation:45-50KW) |

| Motor |

37KW(Siemens) |

|

Winding method

|

manual/automatic

|

| Power Supply |

380V/220V(customized) |

| Warranty |

1 Year |

|

Number of tapes

|

4 strips |

|

Screw

|

¢110*3300 mm

|

|

Operation mode

|

PLC touch screen control system

|

| Plastic Processed |

PP polypropylene new material/recycled material

|

Support and Services of pp strapping band making machine:

Our PP strapping equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PP strapping equipment.

2. Analysis of finished product manufacturing costs of PP strapping equipment.

3. Analysis of raw materials used in PP strapping equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PP strapping equipment.

2. Installation, commissioning and training of PP strapping equipment.

3. Repair service of PP strapping equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

8. Training and technical consultation

FQA

:

Q: What are the specifications that the PP strapping production line can produce?

A: Width: 5-19mm, thickness: 0.3-1.2mm.

Q: What's the price of this machine please?

A: We have different extrusion capacities and different models, and the corresponding prices are also different.

Q:Can the length of the PP strapping production line be customized?

A: YES

Q:What is the transaction method of PP strapping production line?

EXW ,FOB,CIF

This product is packaged and shipped in the standard packaging of PP Strap Making Machine. The packing crate is made of wood and is designed to protect the product from any damages during transit. The dimensions of the crate are 50cm x 50cm x 70cm, and it weighs approximately 21kg. The box is secured with strong straps, and bubble wrap is used to fill the gaps. The product is also covered with a plastic film to protect it from dust and moisture. The product will be shipped out within 5 business days from the date of purchase.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews