110mm Screw Diameter Polypropylene Strap Making Machine with Paper/Core Type

Product Description of pp strapping band making machine

The main components of PP strapping equipment:

Extruder---- core component, heats and melts PP particles and then extrude them into shape.

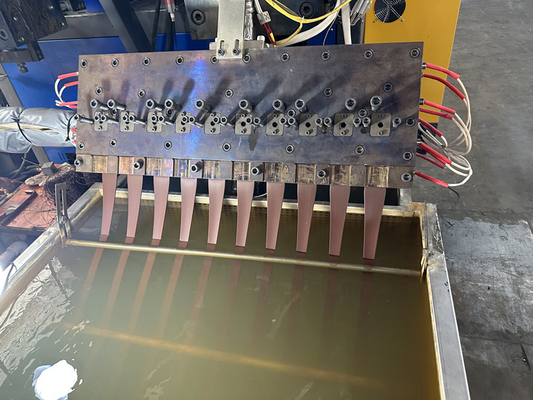

Die head---- determines the shape and size of the plastic strap.

Cooling system----quickly solidifies the extruded plastic strap through water cooling or air cooling.

Tractor---- pulls out the cooled plastic strap to ensure uniform thickness and width.

Oven---- heats the strap embryo and stretches it into shape, stretching ratio: 10-20 times.

Coiler---- winds the plastic strap into a roll for easy storage and transportation.

Control system---- PLC automatically controls each component to ensure stable production.

EXTRUSION PARAMETERS TABLE

Features of the feeding part of PP strapping equipment

PP strapping equipment is equipped with 3 sets of auxiliary feeders,

Dyeing masterbatch can be added to change the color of PP strap

Filling masterbatch can be added to reduce the cost of PP strap

Defoaming agent can be added to eliminate moisture in PP raw materials

PP Strapping Production Line Process Flow

The comprehensive production process includes: Loading → Mixing raw materials → Pre-drying raw materials → Melting and metering raw materials for extrusion → Cooling and forming of raw materials (strip raw materials) → Preheating the oven → First stretching → Second stretching → Embossing → Oven tempering and shaping → Cooling → Finished product winding. Each step is meticulously designed to ensure the highest quality output.

Support and Services

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ

Q: What is the minimum order quantity of the PP strap production line?

A: MOQ: 1 set

Q: What is the extrusion output of the PP strapping production line?

A: We have an extrusion capacity of 80-600KG/H. Different models have different extrusion capacities.

Q: How many strips can the PP strap production line produce?

A: 1-12 strips

Q: What is the price of the PP strap production line?

A: The price varies for different models and can be negotiated.

Q: What is the voltage of the PP strap production line?

A: Standard: 380V/50HZ, which can be customized according to customer requirements.

Q: How long is the delivery date of the PP strap production line?

A: 30-40 Days

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews