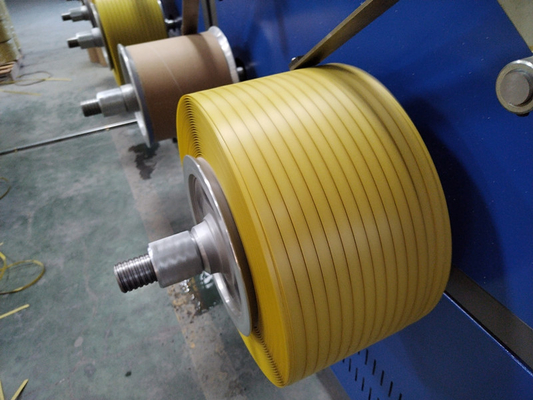

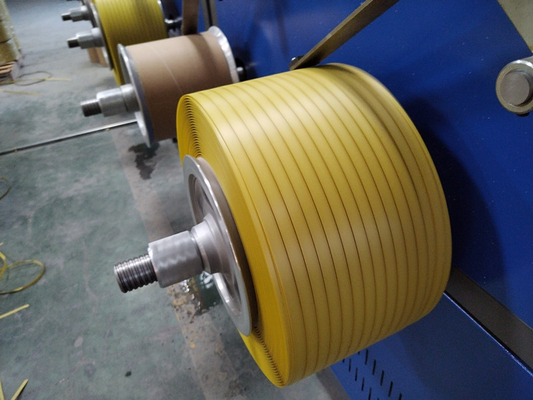

Customized plastic machinery 5-15mm PP strapping production line PP strapping machine for 100-600KG/H production capacity

Product Description of pp strap manufacturing machine:

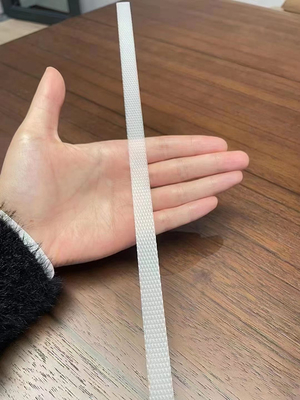

PP strapping tape production line is a high-end intelligent extrusion equipment that can produce PP tape: width: 5-19mm, thickness: 0.3-1.2mm

►Raw materials-----PP strapping equipment can produce plastic raw materials:100%recycled materials or PP polypropylene new materials to produce strapping tape;

►Screw-----The equipment adopts high-precision high-quality screws, adopts well-known brands, and has unique parameter design. It has the advantages of large extrusion volume, good plasticization, high hardness and wear resistance; equipped with a quantitative extrusion system, the width and thickness of the produced belts are the same, the error range is small, and it meets the national strapping tape acceptance standards;

►Automatic screen changer------Equipped with a non-stop automatic screen changer, the screen does not need to be stopped, and the efficiency is maximized. 4-net circulation large-area filtration does not require frequent screen changes.

Features of pp pp strap manufacturing machine:

The PP strapping tape production line has the following characteristics:

High degree of automation-----PP strapping tape production line is basically automated from raw material input to finished product output, reducing manual intervention and improving production efficiency.

High production efficiency-----Adopting advanced equipment and technology, it can produce quickly and continuously to meet large-volume needs.

Stable product quality-----Automatic control ensures that parameters such as product thickness, width and strength are consistent and the quality is stable.

Technical Parameters of pp strap manufacturing machine

| Parameter |

Value |

| Name |

PP Strap Making Machine |

| Strap Material |

PP Recycle Material/New Raw Material |

| Strap Color |

Red/ Green/ Black/ Yellow/ White |

|

Screw

|

¢110*3300mm |

| Power Supply |

380V/220V |

|

Host inverter

|

37KW (INVT) |

|

Motor power

|

37KW (Siemens) |

|

Paper core diameter

|

¢200*180mm

|

| Width |

5-19mm |

| Thickness |

0.4-1.2mm |

Support and Services of pp strapping band making machine:

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

Packing and Shipping of pp strapping band making machine:

Packaging and Shipping of PP Strap Making Machine

PP strap making machine is packaged and shipped in a wooden box. The box should be reinforced, and the machine should be securely fastened and cushioned with foam to protect against any damage during transportation. The box should be clearly labeled with the product name and shipping information.

The customer should be notified of the shipment of the PP strap making machine, and it is recommended that they request tracking information. The customer should also be informed of the estimated time of arrival and any special instructions that may be necessary for the safe delivery of the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews