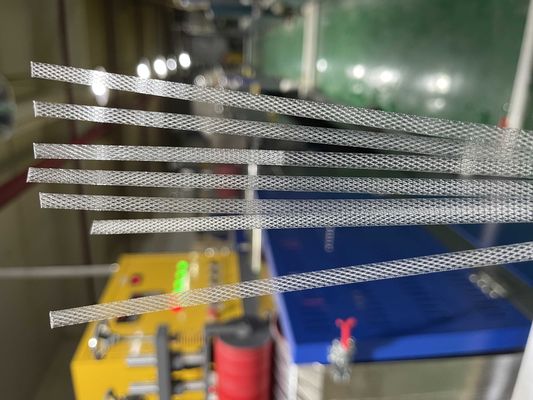

80KW Power Consumption 5-15mm PP Strap Manufacturing Machine for Continuous Production

Product Description of PP strap making machine:

PP strapping equipment is an efficient and highly automated extrusion production equipment. The PP straps produced are widely used in many industries and have stable product quality and broad market prospects.

Main components------

Usually composed of: screw feeder, extruder, cooling water tank, first tractor, stretching oven, embossing machine, shaping oven, flower collecting machine, etc.

Working principle-----

The raw material enters the strong extruder through the feeding system, and the PP strap embryo is pressed out from the die after heating and melting, and the cooling water tank quickly cools and shapes the embryo.

The first tractor transports the PP strap embryo to the stretching oven for heating and stretching, and the second tractor transports it to the embossing machine for embossing. The embossed strapping is eliminated from the internal stress by the shaping oven, and then cooled and shaped again by the shaping water tank, and finally transported to the coiler by the third tractor for winding, completing the production of PP strapping.

Technical Parameters of PP double output making machine:

| Name |

PP Strap Making Machine |

| Trademark |

JiaTuo China |

| Extruder |

Single Or Double Screw |

| Automatic Grade |

Fully Automatic |

| Strap Thickness |

0.4-1.2mm |

| Strap Width |

5-19mm |

| Strap Color |

Red/ Green/ Black/ Yellow/ White |

| Applicable Raw Materials |

Recycled Material And Polypropylene raw material |

| Plastic Processed |

PP |

| Number of strap |

2 straps |

PP strapping equipment:

Main types: can be divided into semi-automatic strapping machine and fully automatic strapping machine.

Semi-automatic baler------requires manual feeding of packaging materials and goods, and automatically completes the baling process.

Fully automatic baler-------can realize a series of operations such as automatic feeding, baling, and cutting, with higher efficiency, and can automatically use electric heat welding technology for baling.

FAQ:

Q: What is the Brand Name of the PP Strap Making Machine?

A: The Brand Name of the PP Strap Making Machine is JIATUO CHINA.

Q: What is the Model Number of the PP Strap Making Machine?

A: The Model Number of the PP Strap Making Machine is JTPP.

Q: Where is the Place of Origin of the PP Strap Making Machine?

A: The Place of Origin of the PP Strap Making Machine is CHINA.

Q: What is the Certification of the PP Strap Making Machine?

A: The Certification of the PP Strap Making Machine is ISO CE.

Q: What is the Minimum Order Quantity for the PP Strap Making Machine?

A: The Minimum Order Quantity for the PP Strap Making Machine is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews