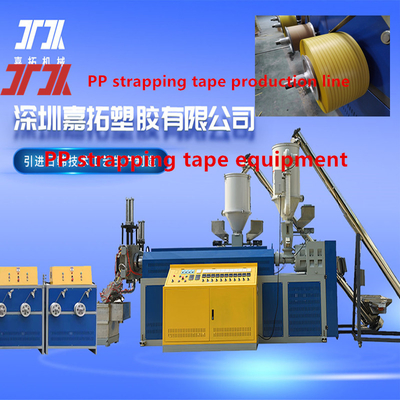

Main features of PP strapping production line

High efficiency----high degree of automation, PLC control system, fast production speed, line speed 200-300 m/min.

High quality----high speed rotation, high output, low power consumption, the finished PP straps produced have good toughness and bending resistance, which meet the requirements of fully automatic strapping machines.

Environmental protection----Use PP new materials or recyclable materials for production, non-toxic, odorless and degradable.

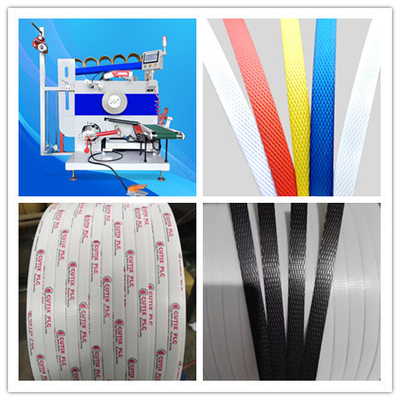

Multi-function----Can produce different specifications of width, thickness, length and weight. Width: 5-19mm, thickness: 0.3-1.2mm.

PP strapping production line process flow:

① Feeding →② stirring →③ pre-drying →④ melting and measuring extrusion →⑤ embryo (belt embryo) cooling and forming →⑥ oven preheating →⑦ primary stretching →⑧ secondary stretching →⑨ embossening → oven tempering and setting → cooling → finished product winding

FeaturesProduct Description of packing belt production equipment:

- Product Name: PP Strap Making Machine

- Strap Speed: >250--300m/min

- Applicable raw materials: Recycled Material And Polypropylene

- Power Supply: 380V/220V

- Strap Material: PP Recycle Material/New Raw Material

- Power Consumption: 100KW

- Material barrel 250-600KG/H

- Gearbox model: 225

- Screw: 110*3300mm

- Plastic Strap Production Machine

- Plastic Strap Manufacture Equipment

- Polypropylene Banding Machine

- Service guaranteed

- Environment-friendly strapping equipment

Technical Parameters:

| Name |

Parameters |

| Name |

PP Strap Making Machine |

| Warranty |

1 Year |

| Screw diameter (mm) |

100mm |

| Strap Color |

Red/Green/Black/Yellow |

| Strap Width |

5-19mm |

| Key Selling Points |

Lead To Germany Japan Technology |

| Power Consumption |

100KW |

| Motor |

Siemens |

Applications of packing belt production equipment:

Working process of PP strapping equipment:

Raw material preparation----Add PP granules into the extruder hopper.

Extrusion molding----PP granules are melted in the extruder and extruded through the mold.

Cooling and shaping----The extruded strapping tape enters the cooling water tank for cooling and shaping.

Traction and stretching---- The traction machine pulls the strapping tape, and the stretching machine performs stretching treatment.

Embossed treatment---- The embossing machine embosses the surface of the strapping tape.

Shaping oven---- Heat and shape the PP tape again to achieve consistent specifications.

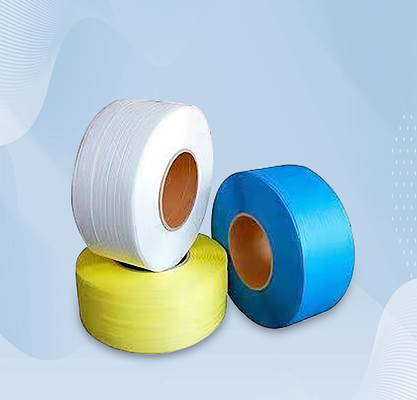

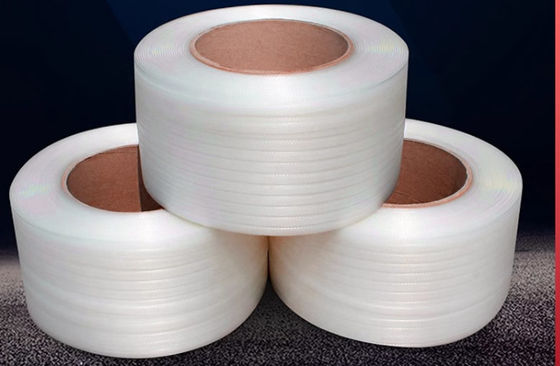

Reeling and packaging----The reeling machine winds the strapping tape into a roll and puts it into storage after packaging.

Technical Support and Service for PP Strap Making Machine

We provide comprehensive technical support and service for the PP Strap Making Machine. Our team of highly skilled engineers and technicians are available 24/7 to provide:

- Remote technical support

- On-site technical support

- Equipment installation and maintenance

- Product and process troubleshooting

- Spare parts supply and replacement

- Software updates and upgrades

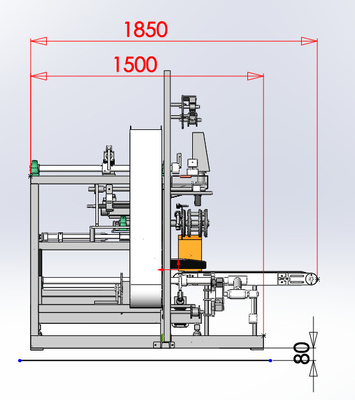

PP strapping tape production line can be equipped with a fully automatic winding machine.

The PP Strap Making Machine is packaged in a secure cardboard box with foam inserts to protect the machine from any potential damage during shipping. The box is labelled with the product information and shipped via a reputable courier service.

Additional packaging options are available upon request as needed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews