100% Recycled Material And Polypropylene PP Strap Making Machine With GUOMAO Motor

Product Description of PP Strap Making Machine

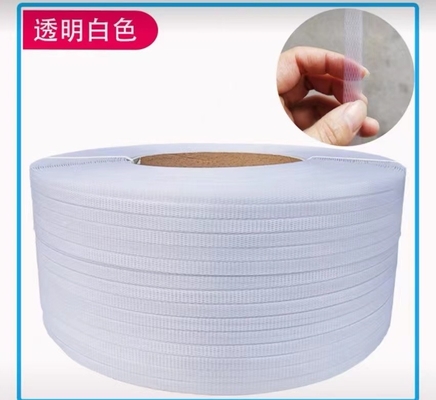

The PP Strap Making Machine is a plastic strap manufacture equipment from JiaTuo China. It is widely used in the production of polypropylene strapping with thickness ranging from 0.4 to 1.2mm. The recycled material and polypropylene can be used as raw materials. The machine is easy to operate and can provide efficient and accurate strapping production. It is a reliable and cost-effective plastic strap production machine for both industrial and commercial strapping applications.

Technical Parameters of PP Strap Production Machine

| Key Selling Points |

Technical Parameters |

| Introduction of German and Japanese advanced technology |

Polypropylene Strap Production Machine, Plastic Strapping Manufacturing Machine, Plastic Strap Manufacture Equipment |

| Power Consumption |

100KW |

| Video outgoing-inspection |

Provided |

| Strap Thickness |

0.4-1.2mm |

| Screw diameter (mm) |

90-130mm (customized as capacity needing) |

| Plastic Processed |

PP |

| Warranty |

1 Year |

| Strap Material |

PP Recycle Material/New Raw Material |

| Strap Tension |

Adjustable |

| Winder |

Double Station Winder |

Features of PP strip Making Machine

1. Production of raw materials: 100% recycled material or 100% new material production, but also according to customer requirements with unique production formula, appropriate addition of calcium carbonate and other additives to reduce costs, improve product competitiveness;

2. The various specifications and grades produced can be applied to all kinds of automatic unmanned balers and semi-automatic balers at home and abroad;

3. High output of the equipment, the finished product with a single line speed of 300m/min; The production of packaging belt specifications are complete, width 5-19MM, thickness 0.4-1.2MM;

4. High precision and high quality screw, using world famous brand, unique parameter design, with large extrusion capacity, good plasticization, good material compatibility, wear resistance and other advantages;

5. Foreign CNC machine tool cutting, high-precision die parts, so that the product molding quality is stable, width, thickness error range is less than the international packaging belt industry acceptance range;

6. Unique five-roll traction system, stable traction, stable operation of equipment, reduce failure rate, convenient maintenance;

Packing and Shipping

Packaging and Shipping for PP Strap Making Machine

The PP Strap Making Machine will be carefully packaged in plastic film to ensure it is protected during shipping. The film will be labeled with the shipping address and a list of contents.

The PP Strap Making Machine will be shipped via a reliable carrier, like EMC/MSK/ONE etc. The delivery time will depend on the shipping destination, but should be within 5-7 business days.

FAQ

- Q: What is the Brand Name of the PP Strap Making Machine?

- A: The Brand Name of the PP Strap Making Machine is JIATUO CHINA.

- Q: What is the Model Number of the PP Strap Making Machine?

- A: The Model Number of the PP Strap Making Machine is JTPP125

- Q: Where is the Place of Origin of the PP Strap Making Machine?

- A: The Place of Origin of the PP Strap Making Machine is China.

- Q: What is the Certification of the PP Strap Making Machine?

- A: The Certification of the PP Strap Making Machine is IS CEO.

- Q: What is the Minimum Order Quantity of the PP Strap Making Machine?

- A: The Minimum Order Quantity of the PP Strap Making Machine is 1 SET.

- Q: What is the Price of the PP Strap Making Machine?

- A: The Price of the PP Strap Making Machine is Negotiable.

- Q: What is the Packaging Details of the PP Strap Making Machine?

- A: The Packaging Details of the PP Strap Making Machine is plastic film.

- Q: What is the Delivery Time of the PP Strap Making Machine?

- A: The Delivery Time of the PP Strap Making Machine is 30-40days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews