Packaging machinery PP strapping equipment PP plastic strapping extruder for automatic screen changer

Quick Detail Of PP Strap Making Machine

PP strapping tape, also known as polypropylene strapping tape, is a strapping tape made of polypropylene brushed resin as the main raw material. It has superior characteristics:

Good plasticity-----can be formed into various shapes and sizes as needed, width: 5-19mm, thickness: 0.3-1.2mm.

Strong breaking tensile force----has a high load-bearing capacity, suitable for various occasions that require packaging and fixing.

Bending resistance----will not easily break or damage even after multiple bending.

Low density----relatively light weight, easy to carry and use.

PP strapping tape is also very easy to use, so it is widely used in many fields, including but not limited to logistics, packaging, transportation, electronic products, hardware, home appliances, clothing, etc.

Specification Of PP Strap Production Line

Features Of Plastic PP Extrusion Line(1) Safety and environmental protection:safe for use, not easy to hurt, according with EU environmental directives, for example ROSH.

(2) Low cost:It is the most cost-effective in new environmentally friendly packaging materials products.

(3) Easy to use:Suitable for fully automatic balers, manual balers and other packaging machinery quickly and convenient to use.

(4) Excellent toughness: Between -50 ~ 100 ºC temperature, it is fully capable of normal use, and maintains excellent flexibility.

(5) Look beautiful: Finish bundled items look beautiful, does not pollute the items, never rust.

(6) Very good strength: Can provide up to 470 MPA tensile strength to protect the safety of Strapping.

FAQ ABOUT PP STRAPPING BAND EXTRUSION LINE

1. For PP(polypropylene) strapping band extrusion line

* What about the output of PP strapping band extrusion line? 150-600kg/hr.

* What about the size of strap that the PP strap machine can make? Width: 5-19mm; Thickness: 0.35-1.0mm;

* What about the installation power of the PP strap machine? 80-150kw;

2. For PET(polyester) strapping band extrusion line

* What about the output of PET strapping band extrusion line? 20-800kg/hr.

* What about the size of strap that the PET strap machine can make? Width: 9-32mm; Thickness: 0.35-1.2mm;

* What about the installation power of the PET strap machine? 200-400kw;

strength when welding strap.

5.Melt filter with two pistons with air venting design and back flushing.

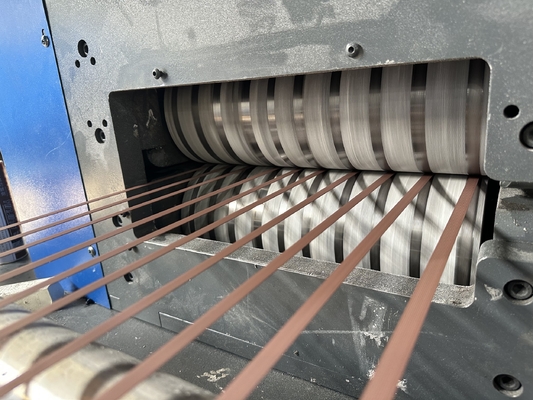

6.Number of strap:1,2,4,6,Width: 5mm-22mm,Thickness: 0.5mm-1.5mm

7.Workers: 2 -3 workers per shift, 12 hours/shift.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews