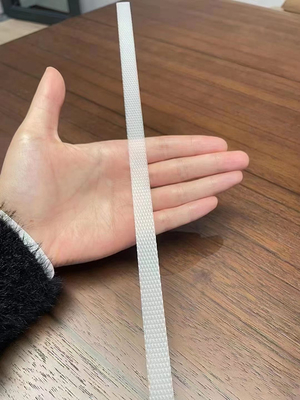

PP Strapping Making Machine of Pack and tape equipment:

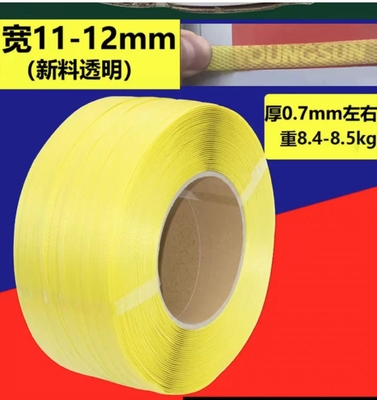

The PP strapping tape production line can produce PP strapping tapes of different colors according to customer requirements, including: red, green, blue, black, yellow, transparent, white, etc.

The PP strapping tape production line can use twin-screw extrusion or single-screw extrusion according to customer requirements, and can produce all-plastic PP tapes or sandwich PP tapes.

PP strapping equipment can be customized according to customer requirements and can extrude 2-12 PP straps at the same time.

Working process of PP strapping equipment:

Raw material preparation----Add PP granules into the extruder hopper.

Extrusion molding----PP granules are melted in the extruder and extruded through the mold.

Cooling and shaping----The extruded strapping tape enters the cooling water tank for cooling and shaping.

Traction and stretching---- The traction machine pulls the strapping tape, and the stretching machine performs stretching treatment.

Embossed treatment---- The embossing machine embosses the surface of the strapping tape.

Shaping oven---- Heat and shape the PP tape again to achieve consistent specifications.

Reeling and packaging----The reeling machine winds the strapping tape into a roll and puts it into storage after packaging.

PP PACKING STRAP SPECIFICATION TABLE:

|

Model

|

Strap Width

|

StrapThickness

|

Pull

|

Gross weight

|

Net weight

|

Paper core

|

Length

|

| PP-05050 |

5.0mm |

0.45mm |

>50kg |

10kg |

8.8kg |

200*180mm |

7000m |

| PP-05050 |

5.0mm |

0.50mm |

>60kg |

10kg |

8.8kg |

200*180mm |

6000m |

| PP-06050 |

6.0mm |

0.50mm |

>65kg |

10kg |

8.8kg |

200*180mm |

5000m |

| PP-08050 |

8.0mm |

0.50mm |

>90kg |

10kg |

8.8kg |

200*180mm |

4200m |

| PP-09050 |

9.0mm |

0.50mm |

>85kg |

10kg |

8.8kg |

200*180mm |

3100m |

| PP-09060 |

9.0mm |

0.60mm |

>90kg |

10kg |

8.8kg |

200*180mm |

2550m |

| PP-09070 |

9.0mm |

0.70mm |

>110kg |

10kg |

8.8kg |

200*180mm |

2300m |

| PP-09080 |

9.0mm |

0.80mm |

>120kg |

10kg |

8.8kg |

200*180mm |

2500m |

Other specifications:PP-12050 PP-12060 PP-12070 PP-12080 PP-13550 PP-13560 PP-13570 PP-13580

PP-15050 PP-15060 PP-15070 PP-15080 PP-15100 PP-18080 PP-19060 PP-19070 PP-19080

Applications of Pack and tape equipment:

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

- Q: What is the Brand Name of the PP Strap Making Machine?

- A: The Brand Name of the PP Strap Making Machine is JIATUO CHINA.

- Q: What is the Model Number of the PP Strap Making Machine?

- A: The Model Number of the PP Strap Making Machine is JTPP.

- Q: Where is the PP Strap Making Machine made?

- A: The PP Strap Making Machine is made in China.

- Q: What is the Certification of the PP Strap Making Machine?

- A: The Certification of the PP Strap Making Machine is IS CEO.

- Q: What is the Minimum Order Quantity of the PP Strap Making Machine?

- A: The Minimum Order Quantity of the PP Strap Making Machine is 1 SET.

- Q: What is the Price of the PP Strap Making Machine?

- A: The Price of the PP Strap Making Machine is Negotiable.

- Q: What is the Packaging Details of the PP Strap Making Machine?

- A: The Packaging Details of the PP Strap Making Machine is plastic film.

- Q: How long is the Delivery Time of the PP Strap Making Machine?

- A: The Delivery Time of the PP Strap Making Machine is 30-40days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews