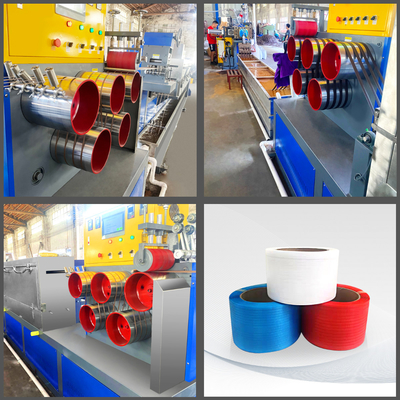

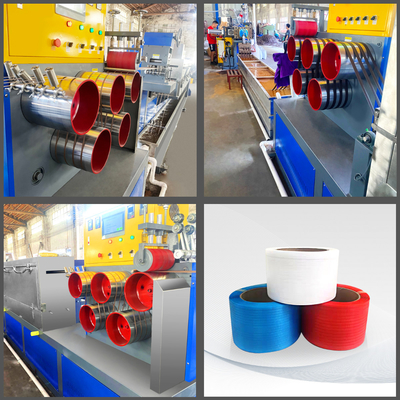

Polypropylene Strap Making Machine 3.5KW Power Consumption 0.4-1.2mm Thickness

Product Description:

The whole machine of the PP strapping production line adopts a PLC control system, a PLC touch screen control system, which replaces the potentiometer to control the speed regulation, can memorize the production parameters, and is more convenient to operate. PLC touch screen control system, which replaces the potentiometer to control the speed regulation, can memorize the production parameters, and is more convenient to operate.

PP strapping equipment winding machine: Automatic winding, semi-automatic winding

Main functions:

1) use the servo motor to lay the cable, and wind up the PP STRAP with the width of 5-19mm. Select the corresponding bandwidth through the touch screen to wind up, and there is no need to manually replace the transmission gear.

2) After the winding is completed, the machine will stop automatically, replace the paper tube, cut off the PP STRAP and clamp the pieces to fix the STRAP head, and the winding operation will be carried out automatically, and the whole process will be completed automatically.

3) The winding shaft uses the torque mode of servo motor, and the torque during winding can be set through the touch screen, so that the PP STRAP with different gram weight or width can be wound with appropriate torque, so be best to minimize the bending deformation of the PP STRAP after winding.

Features:

- Product Name: PP Strap Making Machine

- Strap Core Outer Diameter: 200-400mm

- Strap Core Inner Diameter: 76mm

- Strap Core Length: 200-400mm

- Strap Tension: Adjustable

- Strap Thickness: 0.4-1.2mm

- Used for: Polypropylene Strapping Machine, Plastic Strap Manufacture Equipment, Polypropylene Strap Making Machine

Applications:

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:What is the length of the PP strapping tape??

A: L:36 M.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Q:What does the wrapping machine part of the PP strapping equipment look like?

A:Equipped with automatic wrapping machine/semi-automatic wrapping machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews