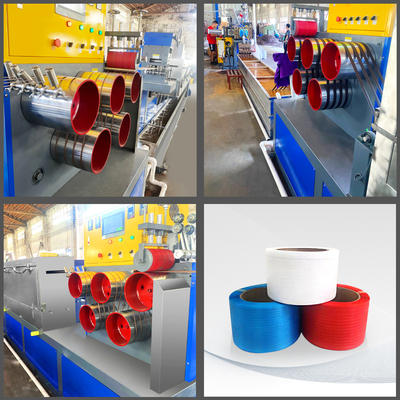

Product Description of pp strapping band making machine:

PP plastic belt equipment is a mechanical equipment used to produce polypropylene (PP) plastic belts, which are widely used in packaging, printing, textile, ceramics, printing, logistics, home appliances and other industries.

1. Raw materials------PP strapping equipment can produce plastic raw materials: recycled materials or new materials to produce strapping;

2. Screw------The equipment adopts high-precision high-quality screws, adopts well-known brands, and has unique parameter design. It has the advantages of large extrusion volume, good plasticization, high hardness and wear resistance; equipped with a quantitative extrusion system, the width and thickness of the produced belts are the same, the error range is small, and it meets the national strapping acceptance standards;

3. Mold-----Foreign CNC machine cutting, high-precision die parts, so that the product molding quality is stable, the width and thickness error range is less than the national strapping acceptance range;

.

Raw materials-----

PP strapping equipment can produce plastic raw materials:

100%recycled materials or PP polypropylene new materials to produce strapping belt

Advantages of pp strapping band making machine:

Easy to operate----The semi-automatic winding machine is simple in design and easy to operate. Workers can learn quickly without extensive training.

Small investment---PP tape making machine is energy-saving and environmentally friendly. It can be produced using PP polypropylene recycled materials and has low manufacturing costs.

Advanced technology-----PP tape making machine has advanced technology and uses high-precision accessories. The PP tape produced is suitable for automatic baling machines and semi-automatic baling machines.

PLC control----PP tape making machine adopts PLC control system, which can save production parameters, simple debugging, stable operation, and clear data at a glance.

Winding machine---PP tape making machine can use automatic winding machine, automatic wiring, automatic roll change, automatic PE film wrapping, reduce labor and improve production efficiency

Applications of pp strapping band making machine:

PP Strap Making Machine for Polypropylene Strap Manufacturing

The JIATUO CHINA JTPP PP Strap Making Machine is the ideal choice for any business looking for efficient and cost-effective polypropylene strap manufacture equipment. This plastic strapping manufacturing machine can produce straps in widths ranging from 5 to 19 mm, and in thicknesses from 0.3 to 1.2 mm. Strap tension is adjustable, and the machine can produce single or multi-color straps.

The PP Strap Making Machine from JIATUO CHINA is certified by IS CEO, and comes with a minimum order quantity of 1 SET. The price is negotiable, and the machine is delivered in plastic film packaging within 40-60 days after the order has been placed.

Whether you need to manufacture plastic straps for industrial packaging, or you are looking to produce custom straps for promotional products, the JIATUO CHINA JTPP PP Strap Making Machine is the perfect solution.

Customization

PP Strap Making Machine

- Brand Name: JIATUO CHINA

- Model Number: JTPP-125

- Place of Origin: CHINA

- Certification: IS CEO

- PP strapping production line

- PP line

- PP strapping production line

- PP packaging tape production line

- PP extrusion line

FAQ:

Q1: What is the Brand Name of PP Strap Making Machine?

A1: The Brand Name of PP Strap Making Machine is JIATUO CHINA.

Q2: What is the Model Number of PP Strap Making Machine?

A2: The Model Number of PP Strap Making Machine is JTPP.

Q3: Where is the PP Strap Making Machine made?

A3: The PP Strap Making Machine is made in CHINA.

Q4: What is the Certification of PP Strap Making Machine?

A4: The Certification of PP Strap Making Machine is IS CEO.

Q5: What is the Minimum Order Quantity of PP Strap Making Machine?

A5: The Minimum Order Quantity of PP Strap Making Machine is 1 SET.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews