High Accuracy Full Automatic Portable Industrial Multifunction Low Price Customize PP Packing Strap Making Machine

DESCRIPTION ABOUT PP STRAP MAKING MACHINE

1. Total equipment power: 100KW

2. Equipment footprint: 38*2.0*4.0M

3.Width: 5-19mm

3. Capacity: 200-600kg / h

4. The equipment voltage is: three-phase 380v/50Hz

5. Equipment bearing TR brand

6. The fuselage frame adopts 100*100*2.5 mm (pass national standard square)

pp strapping band making machine

strapping band making machine

pp strap production line

pp strap manufacturing machine

pp packing strap making machine

pp strapping roll manufacturing machine

| Extruder Model |

single screw 2 straps |

single screw 4 straps |

| Main Motor Power |

80KW |

100KW |

| Overall Size |

30*2.0*4.0M |

38*2.0*4.0M |

| Output |

100KG/H |

200KG/H |

| Voltage |

220V/60Hz |

380V/50Hz |

Raw materials-----The production of plastic raw materials can be made of PP recycled materials or mixed new materials to produce strapping tapes. Calcium carbonate can also be appropriately added according to customer conditions to reduce production costs, increase product profits, and break through market competitiveness.

Strapping machine------The various specifications of the strapping tapes produced can be used for various fully automatic unmanned strapping machines at home and abroad.

Line speed-------High output, the finished product line speed can reach 260-350m/min.

Screw---------High-precision high-quality screws, using well-known brands, unique parameter design, with the advantages of large extrusion volume, good plasticization, high hardness, and wear resistance.

Mould--------Foreign quality CNC machine cutting, high-precision die parts, so that the product molding quality is stable, the thickness error range is less than the national strapping tape acceptance standard.

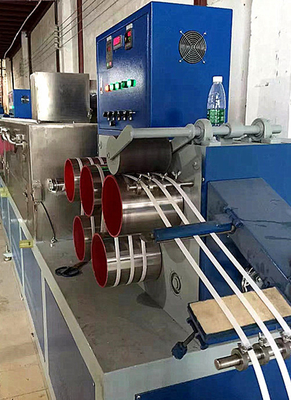

Traction system-------Unique five-roller traction system, stable traction, stable equipment operation, reduced failure rate, and reduced later maintenance costs by more than 80%.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

Q:What is the voltage of PP strapping equipment?

A:380V/50HZ, we support customization

Q:Can the PP strapping production equipment be customized according to the factory length?

A:Yes, we can customize the length according to the customer's factory size.

Q:Where is the PP strapping equipment produced?

A:We are from China.

Q:Can PP strapping equipment provide after-sales service?

A:Yes, we have professional after-sales engineers who provide 24-hour online guidance.

Q:Is the quality of PP strapping equipment stable?

A:We have 30 years of manufacturing experience, and have their own PP packaging belt production plant, equipment quality is stable, the process is worth choosing.

Q:Does PP strapping equipment support customization?

A:We are a manufacturing plant that can customize model size, extrusion capacity, voltage and so on according to customer requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews