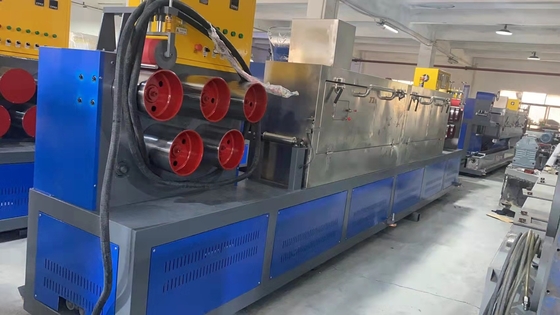

Packaging machinery Customized PP strapping production line PP strapping machine PP strapping equipment with 100-600KG/H extrusion capacity

QUICK DETAIL OF PP STRAP MAKING MACHINE

PP strapping tape production equipment is a mechanical equipment used to manufacture polypropylene (PP) strapping tape. It is widely used in the packaging industry and has more advantages:

High degree of automation----PP strapping tape equipment adopts high-speed automation design, PLC control, simple operation and convenient debugging.

High production efficiency----high speed, continuous production, line speed can reach 200-300 meters/minute.

Stable product quality---Automation control ensures stable product quality, with more than 30 years of experience in manufacturing PP strapping tape equipment.

Energy saving and environmental protection----PP strapping tape equipment adopts energy-saving motors and circulating cooling water systems to reduce energy consumption and pollution.

Name: PP strapping production line

Model number: JTPP

Applicable raw materials: New PP particles, PP recycled materials, PP crushed materials

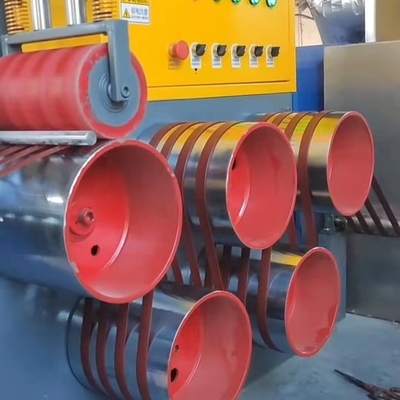

Number of screws: 1-2 Screw

Number of extruded belts: 2-12 straps

Width range: 5-19mm

Thickness range: 0.4-1.2mm

Production capacity: 200-600kg/h

Installation size: L38*W2.0*H4.0(m)

SPECIFICATION OF STRAPPING MAKING MACHINE

| Model |

PP-2 |

PP-4 |

PP-6 |

PP-8 |

PP-10 |

PP-12 |

| Raw material |

PP polypropylene new material/recycled material |

| Number of tapes |

2 |

4 |

6 |

8 |

10 |

12 |

| Width(mm) |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

5-19 |

| Thickness(mm) |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

0.4-1.2 |

| Line speed(m/min) |

≧260-300 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

110 |

125 |

135 |

135 |

135 |

| Reducer model |

200 |

220 |

250 |

280 |

280 |

280 |

| Winding machine |

Automatic winding machine /Semi-automatic winding machine |

| Screen Changer |

Automatic/Manua |

| Production capacity 24H |

2.5-3T |

6-7T |

8-9T |

10-11T |

12-13T |

13--14T |

FEATURES ABOUT PP PACKING MACHINE

PP strapping production line can produce PP strapping tapes of different colors according to customer requirements, adding different dyeing masterbatches,

including: red, green, blue, black, yellow, transparent, white, etc.

PP strapping production line can use single screw/twin screw extruder to produce all-plastic PP straps or sandwich PP straps according to customer requirements.

PP strapping production line can use fully Automatic winding machine or semi-automatic winding machine according to customer requirements to reduce production costs.

About After-sales

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP tape making machine.

3.Raw materials that can be used for PP tape making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

If you do not need us to install and debug the equipment on site, we will provide various online after-sales and discussion services.

FAQ ABOUT PP STRAPPING BAND EXTRUSION LINE

Q: What are the specifications that the PP strapping production line can produce?

A: Width: 5-19mm, thickness: 0.3-1.2mm.

Q: What's the price of this machine please?

A: We have different extrusion capacities and different models, and the corresponding prices are also different.

Q:Can the length of the PP strapping production line be customized?

A: YES

Q:What is the transaction method of PP strapping production line?

EXW ,FOB,CIF

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews