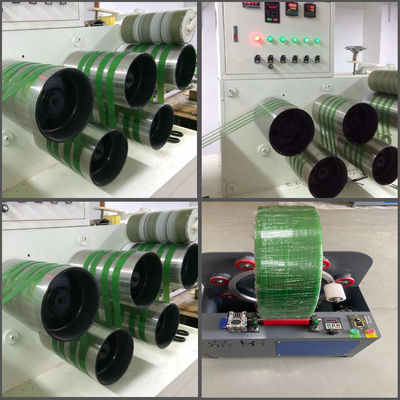

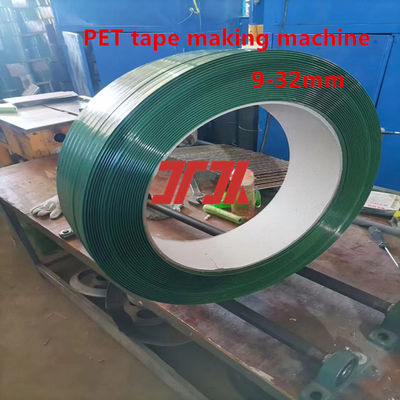

High-speed PET strapping production line 9-32mm PET strapping machine PP PET strapping

PRODUCT DESCRIPTION

Descripition:

This production line can produce different with and thickness of PP PET strap according to client's requirement. This extrusion line is mainly for producing PP PET strap. The raw material can be 100% recycled material, which can reduce the produce cost and get a good profit. And the PP PET belt is the substitution of the steel strap and has lots of advantages such as good extension, high temperature resistance, easy use, etc

The PET /PP packing belt has the characteristic of high stretch-resistant,low extend rate,

impact-resistant,good flexible,easy for operate ,cheap and safe.

EXTRUSION PARAMETERS TABLE

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

100% Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Winding machine |

Automatic winding/ Semi-automatic winding |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

Why do we need to add PET toughening agent to PET plastic steel belt?

What is the role of toughening agent?

THE MAIN FOLE OF PET TOUGHENING AGENT:

Improve impact resistance------By increasing the toughness of PET, it reduces its brittle fracture when impacted.

Improve processing performance------Reducing processing temperature, reducing energy consumption, and improving fluidity to make processing smoother.

Enhance flexibility-------Make PET material softer and suitable for application scenarios that require flexibility.

Improve heat resistance-------Some toughening agents can improve the heat resistance of PET, allowing it to maintain stable performance at high temperatures.

Features of PET packing strap production line:

1. The machine adjusts is conversion motor as power source .

2. The mechanical transmission adopts soft connection.

3. Its rotation is exact and smooth, saving power and low noise.

4. PET has advantages ,such as good stiffness , high temperature resistant ,its specific gravity is 1/5 the one of steel.

5. It is mainly suitable for packing for various trades.

6 Its characteristics: high tensile strength ,small percentage elongation, resistance to impact, not easy to be broken ,cheap, good softness, convenient operation, safe and reliable .

7. In the world ,it is an ideal substitute of steel belt.

8. It is widely used in paper making, wooden products, textile cotton and fiber ,color metal, canned products, chemical , metallurgy, power cable, aluminum.

9.Plastics shaped materials and other products and various kind of trays.

10.The use of the product is convenient, it can adopt common steel fastening for connection.

11.It also is suitable for various kinds of hand-operated of table packing machine and large auto packing machine of enterprises.

12.It adopts hot-melting connection sticks.

FAQ

1. Q: How can I purchase your goods?

A: Please choose your perfect item and tell us your size, quantity and packing you want.

2. Q: How long is the lead time?

A: Normal order within 10-30 days after deposit.

3. Q: Do you offer sample?

A: Samples can be sent for your reference, but charge is required, after making formal order, the cost of samples will be cut from the total amount.

4.Q: What is the MOQ on your products?

A: Small quantity can be acceptable, depends on the stock.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews