6000L Pre-drying Barrel PET Strap Making Machine Packing Belt Machinery With Automatic Winder

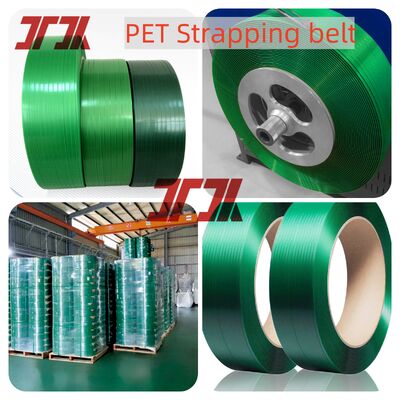

Polyester Strappiing Band(PET strap) is a kind of high tensile plastic packing starp produced with PET as raw material. It has the advantages of high strength, high tensile force, good toughness, no pollution and unlimited export.

Parameter of PET strap production line

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h |

| 4 |

Product size |

Width:9-32mm

Thickness:0.6-12mm |

| 5 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW |

| 6 |

Cooling tower capacity |

30T/H or 50T/H |

| 7 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M |

Advantages of JIATUO PET strap making machine

1. High-efficiency PET mixing, dehumidification, drying, and feeding system, including a drying system, a dehumidification system, and an automatic feeding system.

2. High-efficiency single-screw extruder, gearbox bearings: FSB brand, featuring a specially designed screw and barrel, equipped with an intelligent PLC control system, Invt frequency converter, and Guomao motor.

3. Filtration system uses a high-filtration-area single-cylinder filter. Depending on the raw material, the filter element can be replaced for 5-6 days, greatly improving production efficiency.

4. Cooling water tank: High-precision cooling water tank, made of specific steel, with high wear resistance and good sliding performance. Automatic control of water temperature and level.

5. First preheating unit

Comprising 5 gear-driven preheating rollers, equipped with an oil temperature controller for controlling roller temperature. Gear drive ensures stable operation and low noise.

6. Specially designed heating furnace

The heating furnace is used for stretch heating, featuring rapid heating speed, and is specifically designed for products with special tensile strength requirements.

7. Improved Second Stretching Unit

Composed of a motor, reducer, five traction steel rollers, and drive gears. Equipped with an oil temperature controller with a digital display for roller temperature control. Speed is controlled by a frequency converter.

8. Fully Automatic Winding Machine

This 100% fully automatic winding machine is significantly different from standard winding machines on the market. It is easy to operate, saves more labor, and greatly reduces production costs.

Application of PET strapping

1. The PET packaging belt is lightweight for easy handling and operation. It has high tensile strength, suitable for binding heavy goods. It has good corrosion resistance to acids, alkalis and other chemical substances. It is not absorbent, suitable for use in humid environments. It is recyclable and meets environmental protection requirements.

2.PET pure quality. Good toughness. Resistant to acid and alkali corrosion, and it is difficult to crack repeatedly.

3. Smooth cross section without scraping hand-collapse smooth neat and beautiful.

4. Width and length are sufficient, and packed firmly.

Our advantages

1.WHY CHOOSE US

We are the Professional manufacturer to develop the plastic extrusion machines in Shenzhen. Machine quality and customer satisfaction is our pursuit.Be sure we have the strength to provide you with quality machines and perfect service.

2.WHAT SERVICES DO WE OFFER?

Pre-sale communication → Design proposal, signature confirmation→Customized production→ Test machine before shipment →Package &

delivery→ Engineer installation→Training operator → Technical support

3.PAYMENT TERMS:

30% of total amount should be paid by T/T as down payment ,the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C by payment(at sight).

4.DELIVERY CONDITIONS:

4.1 Delivery condition: EXW, FOB Shenzhen port or CIF destination Port.

4.2 Delivery terms: Within 30-50 working days after receipt of advanced payment, the seller should inform the buyer to do inspection,the seller should finish packing of goods and ready for shipment within 15 working days after the seller receipt the full payment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews