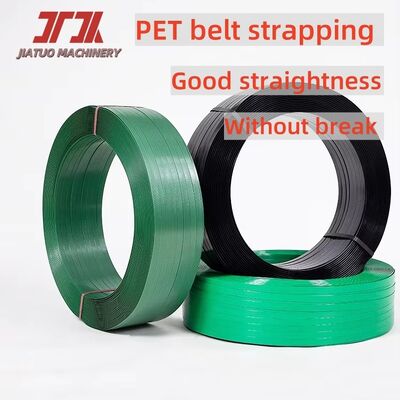

9-32mm Automatic PET Strap Extrusion Line With High-output Packing Belt 150m/min Running Speed

Description of PET plastic straping belt making machine, PET Packing Strap Extrusion Machine

PET packing strip is widely used in packing applications, it can replaced the steel strap for packing application, as its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

Technical of JIATUO PET belt production line

|

Model

|

Capcity (kg/h)

|

Strap Size

|

Power(kw)

|

Manpower

|

|

JT-PET90

|

150-180KG/H

|

9-32mm

|

150

|

1-2

|

|

JT-PET110

|

300-330KG/H

|

9-32mm

|

200

|

1-2

|

|

JT-PET125

|

400-450KG/H

|

9-32mm

|

250

|

2-3

|

|

JT-PET130

|

480-500KG/H

|

9-32mm

|

300

|

2-3 |

PET strap making machine introduction

- Dehumidificater and dehumidification barrel

As PET is easy to absorb moisture in the air, it must be fully dried. At the same time, in order to prevent bonding during drying, crystallization equipment needs to be configured.

Equipped with a uniquely designed PET screw that integrates separation and mixing functions, ensuring uniform material plasticization. Key benefits include high extrusion capacity, excellent plasticizing, superior hardness, and high wear resistance.

- Filter, Melt Pumb, Exrusion Die Unit

It is controlled by PLC pressure closed loop control system. The pressure sensor will transmit signals, and PLC is used to control the speed of melt pump and extruder, so as to stabilize the extrusion of PET materials

The oven is heated by electric power. Heating air is spread evenly by fans.

In the oven, the PET strap will be stretched first time.

The winder could be designed into servo motor unit, inverter motor unit and torque motor according PET or PP materials.

The unique back tooth shaft is used to make the packing belts neatly arranged without overlapping and no horn shape, so that the packing belts maintain a good straightness, which is more suitable for the use of automatic packing machines, and ensures that the automatic equipment conveyor belts are in place. Do not drop the belt.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews