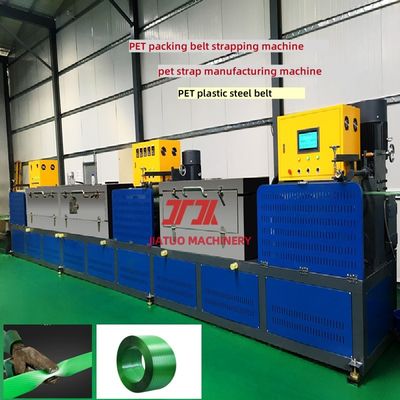

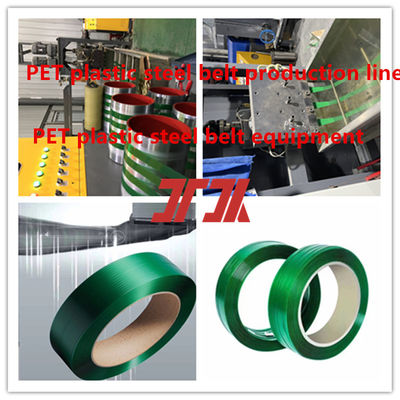

PET strapping production line 9-32mm PET strapping machine high-speed PP/PET strapping production line

Product Description of PET pet belt manufacturing equipment:

PET strapping production line is a high-speed, intelligent, environmentally friendly plastic equipment, its advantages:

RAW MATERIALS

PET plastic steel belt can use raw materials: 100% bottle flakes or crushed materials or thickening granular materials

1. Bottle flakes--- waste mineral water, Sprite, Coke and other bottle flakes as raw materials, after crushing, cleaning, drying materials.

2. Crushed materials---- finished PET plastic steel belt after crushing, screening, cleaning, drying raw materials;

3. Thickening granular materials----PET crushed materials after processing, cleaning, thickening granular materials

Features:

Screw----The PET plastic steel belt production line extruder uses a PET-specific screw with unique parameter design. The screw has a unique separation and mixing effect, ensuring uniform plasticization of the raw materials. It features high extrusion volume, good plasticization, high hardness, and high wear resistance.

Filter----- A three-dimensional folded ultra-large area filter device. The unfolded area of the filter screen is 30 times larger than that of traditional flat filter screens; the filter mesh can reach 80 mesh. A unique screen changing device greatly reduces screen changing time and improves work efficiency.

Dehumidifier------ A rotary honeycomb dehumidification and drying system is used for raw material drying. A dew point of -50℃ ensures that the moisture content of the raw materials is ≤50PPM, while also having a solid-phase condensation and thickening effect.

Technical Parameters of PET pet belt manufacturing equipment:

| Item |

Technical Parameters |

| Winding method |

Manual/automatic |

| Control System |

PLC Computer Touch Screen |

| Switchgear |

Schneider |

| Color |

REQUIREMEN BY CUSTONMER |

| Model |

100*2900mm |

| Speed |

100-260m/min |

| Strap Width |

9-32mm |

| Type |

Plastic Extrusion Machine |

| Host inverter |

(INVT) |

| Strap Thickness |

0.6-1.2mm |

| Key Features |

SIMENS control system, double cylinder / single cylinder winding method, Memory Parameter |

Packing and Shipping of PET pet belt manufacturing equipment:

Packaging and Shipping of PET Strap Making Machine

The PET Strap Making Machine will be packaged and shipped using high-quality materials to ensure its safe and secure delivery to the customer. The packaging process will be carried out with utmost care to prevent any damage during transportation.

The machine will be packed in a sturdy wooden crate to protect it from any external impact during transit. The crate will be sealed with strong adhesive tapes to prevent any tampering or opening during shipment.

Inside the crate, the machine will be further protected with bubble wrap and foam padding to provide extra cushioning and shock absorption. This will prevent any potential damage caused by rough handling or bumps during transportation.

The crate will also be marked with relevant labeling and handling instructions to ensure that the machine is handled with care and delivered to the right destination.

Once the machine is packaged and ready for shipping, it will be loaded onto a suitable transportation vehicle for delivery. Our team will work closely with trusted and reliable shipping companies to ensure timely and safe delivery of the machine to the customer's designated location.

Customers can also request for special packaging or shipping arrangements at an additional cost. We strive to provide the best possible packaging and shipping solutions to our customers to ensure the safe and secure delivery of their PET Strap Making Machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews