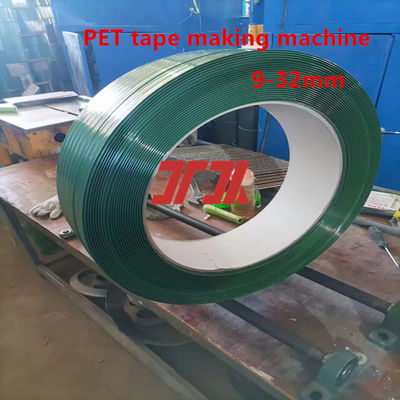

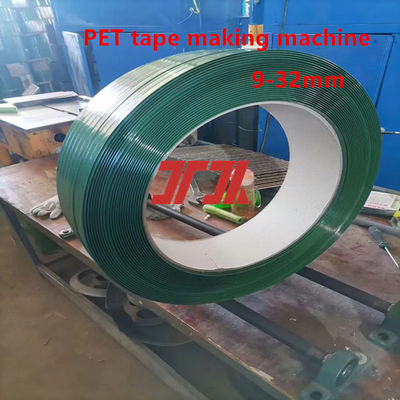

PET plastic-steel strapping equipment high-speed PET strapping machine PP/PET plastic machinery

PRODUCT DESCRIPTION OF PET STRAPPINE MACHINE

PET plastic-steel strapping equipment is a specialized production line that converts recycled or virgin polyethylene terephthalate (PET) into high-strength plastic strapping through a process including melting, extrusion, stretching, shaping, and winding. PET plastic-steel strapping is widely used for heavy-duty packaging in industries such as steel, aluminum, papermaking, chemical fiber, and building materials due to its high strength, corrosion resistance, aesthetic appeal, and recyclability.

Features

Extrusion process-----PET belt making machine uses a special screw for extruder, which is evenly extruded by heating and melting.

Cooling and solidification----The extruded PET belt embryo is then cooled and solidified using a cooling water tank or other refrigerator to ensure that the material maintains its shape and characteristics.

Stretching and orientation----PET belt making machines usually include stretching and orientation parts to improve the tensile strength, flexibility and overall performance of the PET belt. This process aligns the molecules in the PET material to enhance its mechanical properties.

EXTRUSION PARAMETERS TABLE

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Thickness (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

PET packaging belt production line Process Flow

① feeding→② mixing raw materials→③ raw material pre-drying→④ vacuum dehumidification of raw materials→⑤ raw materials melting extrusion→⑥ material embryo expression(with embryo) cooling molding→⑦oven preheating→⑧first stretching→⑨second stretching→⑩embossing→⑪ oven tempering to set the shape→⑫ cooling → ⑬winding(finished product)

Raw materials---

100% PET crushed materials or bottle flakes

After-sales service

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, with capacities ranging from 150-600KG/H

Q: What is the producible width of the PET plastic steel belt equipment?

A: 9-32mm

Q: Can the PET plastic steel belt equipment be customized?

A: Customization supported

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for the PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for the PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews