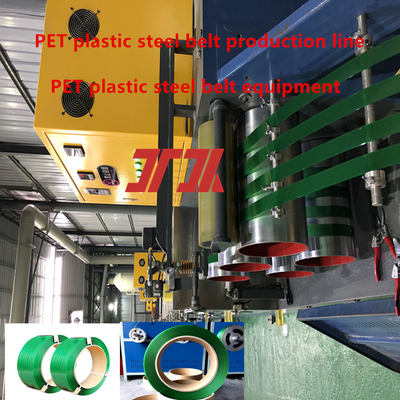

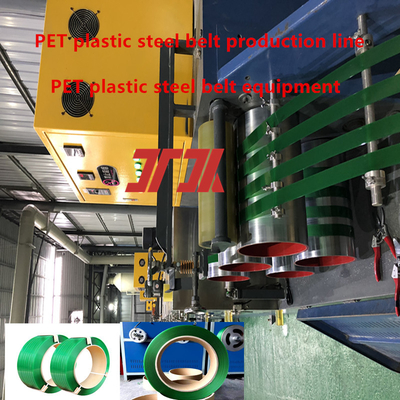

Extruder 9-32mm PET plastic steel strip equipment PET plastic steel strip production line

with 50 CC metering melt pump

Product Description of pet strap production line:

Features of PET plastic steel belt equipment:

1. Adopt special PET extruder dedicated screw, extrusion energy can be customized according to customer requirements.

2. Can use 100% recycled PET bottle flakes or broken material pellets for production.

3. The main machine extrudes evenly, the die head flow channel extrudes stably, and the whole line is automatically controlled by PLC.

4. According to different requirements, the coating material is replaced to make the strap have better stretching ability.

5. Equipped with melt filter, ventilation design and backwashing function.

6. Number of straps: 1-8 straps, support customization.

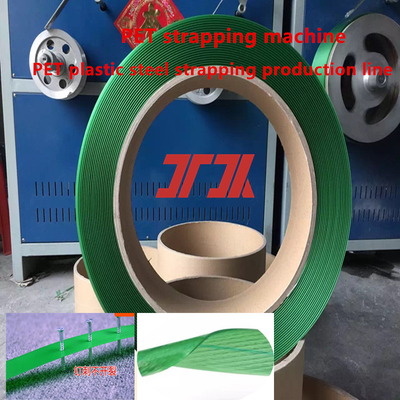

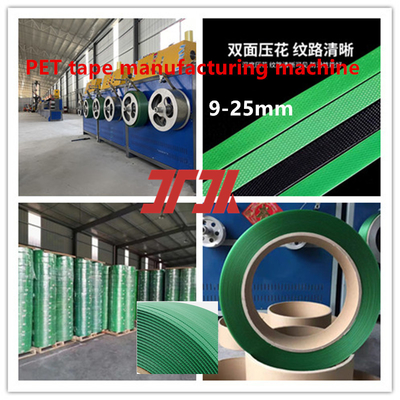

PET strapping production line process flow

① Loading →② Mixing raw materials →③ Pre-drying raw materials →④ Vacuum dehumidification of raw materials →⑤ Melting and metering extrusion of raw materials →⑥ Cooling and forming of raw materials (with raw materials) →⑦ Preheating the oven →⑧ Primary stretching →⑨ Secondary stretching →⑩ Embossing →⑪ Oven tempering and shaping →⑫ Cooling →⑬ Finished product winding

Features of pet strap production line:

- Product Name: PET Strap Making Machine

- Solid-state relay: Taiwan Yangming

- Switchgear: Schneider

- Winding method: Manual/automatic

- Strap Thickness: 0.4-1.2mm

- Brickyard: Suitable for brickyard, metal, steel, and aluminum

- Brewery: Suitable for brewery

- PLC control system: Equipped with PLC control system

- Memory Parameter: Memory parameter setting

- Service guaranteed: YES

EXTRUSION PARAMETERS TABLE

| Name |

PET packing strap making machine |

| Applicable raw materials |

100% bottle flakes or crushed materials |

| Number of screws |

Single Screw |

| Screw model |

150 |

| Number of extruded belts |

6 |

| Width range |

9-32mm |

| Thickness range |

0.4-1.2mm |

| Production capacity |

600-650kg/h |

| Metering Pumps |

150CC |

How to save energy in PET plastic steel belt equipment:

Our machine is in 24-hour non-stop production. If you stop production for 12 hours,

a lot of power loss will be generated when starting up. This machine is a high-speed, environmentally friendly and intelligent machine.

It mainly needs to be heated for 2-3 hours before starting up.

And the pre-drying barrel and dehumidifier barrel need to be heated for 3 hours to remove moisture, which will generate a lot of electricity. When the temperature of our dehumidifier barrel reaches the set value, the motor will stop running and use heat energy to continue drying.

The same is true for the oven system. When the temperature of our equipment is reached, the motor and heating tube will stop running, which will save a lot of electricity. If you stop halfway, you will need to heat it again, which will waste a lot of electricity.

Support and Services :

Technical Support and Service for PET Strap Making Machine

We offer comprehensive, high-quality technical support and services for PET Strap Making Machines in the form of:

- Installation and assembly assistance.

- Operation and maintenance training.

- Troubleshooting and repair.

- Software and hardware updates.

Packing and Shipping of pet strap production line:

Packaging and Shipping of PET Strap Making Machine

The PET Strap Making Machine will be securely packaged to ensure that it reaches customers in perfect condition. Our packaging is designed to protect the machine from dust, moisture, and other external elements. All components and accessories will be packed separately in individual boxes.

The PET Strap Making Machine will be shipped by air, land, or sea, depending on the customer's location and preference. We will provide tracking information to customers so that they can monitor the progress of their shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews