200kg / H PET Strap Packing Belt Extrusion Line Band Extruding Machine With Automatic Winder

PP packing straps extrusion/production machine

Materials: PET virgin material, or 100% recycling PET flakes and PET crushed material.

Application: This machine can be used to meet the needs of cartons, tobacco, clothing, paper, electronics, wooden boxes, fruit, electrical (such as refrigerators, washing machines, color TV), food and other industries.

PET Strap Production Line Machine List

| NO. |

Item |

Specification |

| 1 |

Power |

According to customer's factory voltage |

| 2 |

Material |

PET raw material or 100% PET bottle flakes recycled |

| 3 |

Capacity |

PETJT90:200kg/h

PETJT100:250kg/h

PETJT125:350kg/h

|

| 4 |

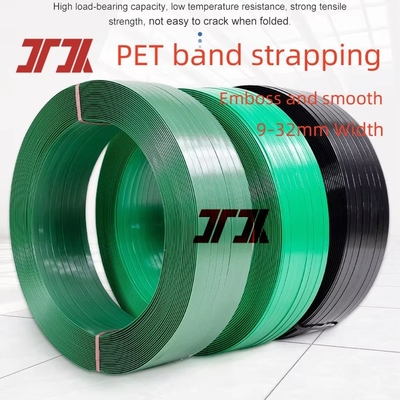

Product size |

Width:9-32mm

Thickness:0.6-12mm

|

| 6 |

Mid-height of extruder |

7000mm |

| 7 |

Installation power |

PETJT90:200KW

PETJT100:250KW

PETJT125:300KW

|

| 8 |

Humidity |

<85% |

| 9 |

Temperature |

0-40 degree |

| 10 |

Cooling tower capacity |

30T/H or 50T/H |

| 11 |

Installation Dimensions |

PETJT90:45*2.0*7.0M

PETJT100:45*2.0*7.0M

PETJT125:60*3.0*8.0M

|

| 12 |

Product color |

Green/Black/Pink/Yellow |

| 13 |

Factory dimension |

35m*(3~6)m*(4~6)m

45m*(3~6)m*(4~6)m

If your factory not big enough,please contact with us,our engineer can according to your size to design

|

Features of PET strap making machine

1.High and stable production efficiency

2.Good quality machine with competitive price

3. can equip XINJIE PLC control, or designed according to customer's requirements

DETAILS ABOUT PET STRAP MAKING MACHINE

1. Components of pp pet packing belt machinery:

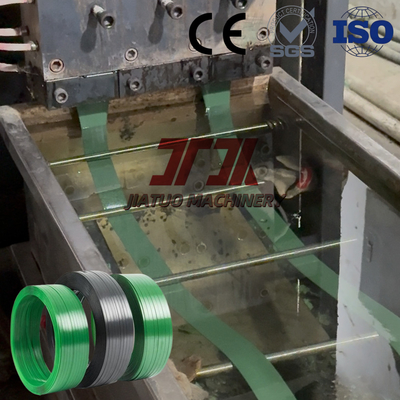

PET Strap Production Line consists of dehumidifying and crystallizing system, extruder, screen changer, mold, oven, haul-off, and winder, etc.

2. Production Process of PET Machinery

Material→ Dehumidifying and Crystallizing → Extruding → Mold → Cooling → Haul-off →Oven Heating →Pre-heating → Drawing and Stretching →Drawing and Stretching → Embossing →Hot Forming → Drawing → Winding

3. Application

With 100% bottle flakes recycled material, to produce various specifications of PET strap. It has been widely used in steel, chemical industry, aluminum, paper making, brick kiln, tobacco, electronics and textile and timber industries.

Our service

1.Free repair within 1 year of guarantee on the condition of operate the machine in the right way, do not include the daily maintaining

2. Our factory provide machine testing when customer come to our factory to see this machine.

3.We provide detail machine technical specification,installation book, operating manual.

4.We can provide engineers to customer's factory to help installation and training workers if customer required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews