400-450kg/H Capacity PET Strap Making Machine With Fully Automatic Winder And Make High Tension PET Strapping

Technical parameters of PET belt 3output production line

| Raw material |

PET tackifier material or PET recycled material |

| Width of final product |

9-32mm |

| thickness of final product |

0.4-1.2mm |

| Max Capacity |

300-330kg/h |

| Manpower |

1-2 persons/shift |

| Machine Dimension |

55*2*8m |

| BRANDS |

| Gearbox: |

GUOMAO |

| Contactor: |

Schneider |

| Temperature controller |

Fotek |

| Inverter |

INVT |

Characteristic of PET strapping

-High strength: PET packaging belt has extremely high tensile strength, usually up to 50%-70% of steel belt, and can withstand large loads.

- Flexibility: Compared with steel belts, PET packaging belts are softer, less likely to scratch the packaging, and safer to operate.

- Corrosion resistance: PET materials are acid and alkali resistant, moisture and rust-proof, and are suitable for a variety of environments.

- Environmental protection: PET packaging tape is recyclable and reusable, meeting environmental protection requirements.

- Lightweight: Lightweight, easy to transport and operate, reducing logistics costs.

- Impact resistance: It has good impact resistance and is suitable for long-distance transportation.

Advantage of JIATUO PP PET strap making machine

1.Enhanced Efficiency: The Fully Automatic Single Double PP Strap Extrusion Line/PET Packing Belt Strapping Production Line Manufacturing Machine is designed to enhance efficiency, making it ideal for businesses in the Machinery Repair Shops and Building Material Shops industries.

2.Robust Performance: With a powerful motor (22 kW, 3 PH 380V 50Hz), this machine is built for durability and can withstand heavy usage. Its core components, including the bearing, motor, pump, gear, PLC, and other essential parts, are all covered under a 1-year warranty.

3.Multifunctional Capabilities: The multifunctional nature of the machine allows it to handle a variety of materials, including PP woven belt, PET packing belt, and wire. It is equipped with a double-screw co-rotating parallel twin-screw design that ensures optimal performance and efficiency.

4.Customization and Automation: As a custom request product, the manufacturer can accommodate specific needs and requirements. The user can choose from a variety of screw diameters and l/d ratios to ensure optimal performance for their specific application.

Special single screw extruder

1) Capacity : 200-500kg/h (according to the requirement of customer)

2) Screw diameter : 80-130mm (according to the capacity to equip with)

3) Ratio of screw : 32:1

4) Motor : 37kw (GUOMAO)

5) Inverter: INVT

6) Temperature controllor : Schneider

7) Heating ring: New type with 20mm rock wool inside to help save electric cost almost 30%

Water cooling tank

Length : 4m

thinkness: 2.0T

Strength part

Traction roll diameter: 270*250mm (according to the configuration capacity to adjust)

Hot strethch oven length :4m

Power :4kw (Invt)

PLC control system

Can setting any language you need.

Can memorize 99 pieces of data for easy retrieval next time

Fans cooling part

Double station winders

1. Paper core specification: ¢406*150mm

2. Torque motor: 10 Nm

3. Band width specification: 9-32mm

4. Return shaft size:¢32*150mm (imported from Taiwan)

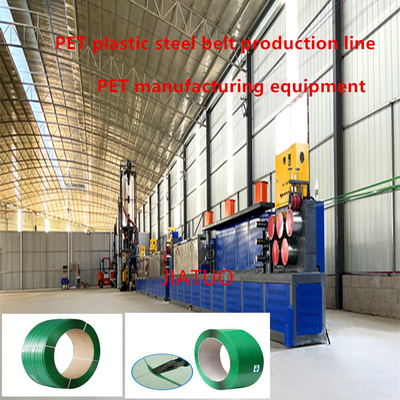

Our Workshop

FAQ

1. Are you trading company or manufacturer?

We are manufacturer, and also provide the business solution to all the friends.

2. Do you have quality certificate?

Yes we have CE, SGS etc.

3. What's the delivery time?

Around 40~50days, however, based on order.

4. What is your overseas service?

We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews