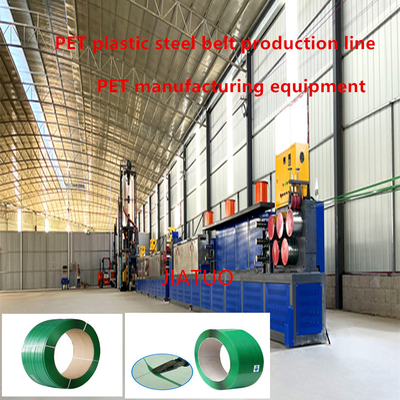

Main description of PET strap production line :

PET pet packaging belt production line features:

1. Better tensile strength-----PET strap production line has the tensile strength of steel belt, good ductility and better impact resistance. Not easy to break, can ensure the safety of product transportation.

2. Small extension-----Although PET strap is a plastic, its extension change is very small, its elongation is only 1/6 of polypropylene, it can maintain tension, and after packaging, the expansion will no longer change.

3. Strong temperature resistance----Experiments have shown that the melting point of PET packaging belt is around 260℃, and it can be used under 120℃ for a long time without distortion, and it has good stability.

4. Good economic benefits----The density of PET packaging tape is 1.30 ~ 1.38g/cm3, which is only 1/6 of the density of steel tape (7.8g/cm3), equivalent to the length of 6 tons of steel tape, and the price of the same unit length is relatively low.

5. Environmental protection----Steel tape will rust due to exposure to air, and the permeability of rust to packaging is high. PET packaging tape is beautiful and will not rust, but it can avoid unnecessary worries. It can also be recycled.

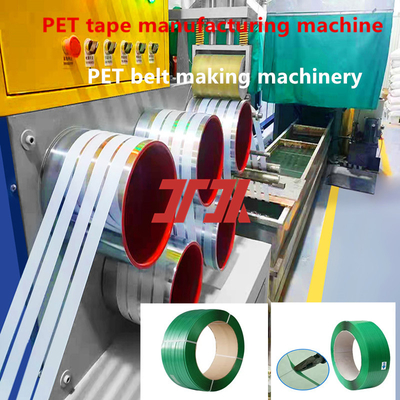

PET strapping production line process flow:

① Loading →② Mixing raw materials →③ Pre-drying raw materials →④ Vacuum dehumidification of raw materials →⑤ Melting and metering extrusion of raw materials →⑥ Cooling and forming of raw materials (with raw materials) →⑦ Preheating the oven →⑧ Primary stretching →⑨ Secondary stretching →⑩ Embossing →⑪ Oven tempering and shaping →⑫ Cooling →⑬ Finished product winding

Application of PET strap

PET packing straps are widely used as a high-performance alternative to steel straps in international packing applications. They offer excellent tensile strength, flexibility, and a low elongation rate, along with superior heat resistance, anti-rust properties, and cost efficiency.

These straps are ideal for bundling a variety of materials, including glass, steel, stone, construction materials, chemical fibers, paper, tobacco, and agricultural products, making them a versatile solution across multiple industries.

Technical parameters:

| Name |

PET packing strap making machine |

| Applicable raw materials |

100% bottle flakes or crushed materials |

| Number of screws |

Single Screw |

| Screw model |

150 |

| Number of extruded belts |

6 |

| Width range |

9-32mm |

| Thickness range |

0.4-1.2mm |

| Production capacity |

600-650kg/h |

| Metering Pumps |

150CC |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews