200-950kg/H Capacity New Pet Strapping Band Production Line With Automatic Winder GUOMAO Reducer

Production description of PET strap making machine

PET strap production line With 100% bottle flakes recycled material, to produce various specifications of PET strap. It consists of dehumidifying and crystallizing system, extruder, screen changer, mould, oven, haul-off, and winder, etc.

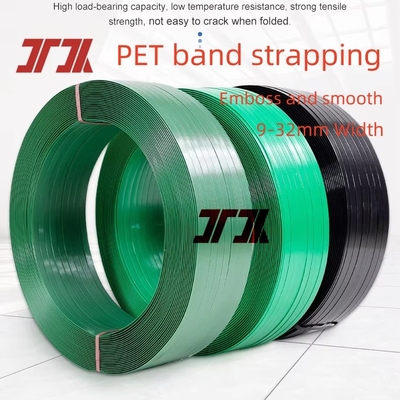

Application of PET strapping

PET packing strip is widely used in packing applications, it can replaced the steel strap for packing application, as its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

Parameter of PET belt making machine

| Raw material |

PET granules or PET recycled material |

| Width of final product |

9-32mm |

| thickness of final product |

0.4-1.2mm |

| Max Capacity |

200-100kg/hour |

| Manpower |

2 persons/shift |

| Machine Dimension |

30-35*6*6m |

| BRANDS |

| Reducer |

GUOMAO |

| Contactor |

GUOMAO |

| Temperature controller |

Schneider |

| Inverter |

INVT |

Photos of PET packing strip belt making machine

Pre-drying and dihumidifucation system

Main machine: Screw melting, 3.5m2 filtration system to filter material impurities, Metering pump and high-precision die head design for extruded materials

Five rolls strench machine: Through the stretching oven preheating will be carried out 2 sections of five-roller roller stretching, so that the stretch ratio to reach the optimal state, the width and thickness of the packing tape small error.

Double station winder: easy to change rolls, neatly wound, with automatic deskew function.

Why choose us

1. Can use 100% recycled bottle flakes material/100% strap regrind

2. The final straps can be packed automatically

3. We specilized in PP PET strap making machine for nearly 30years experience

4. Always have sample machine in our workshop

5. Can take customers to see the running machines

6. Can test the machine for customers

FAQ

Q2.When can I get the price?

A:We usually quote within 24 hours after getting your inquiry if you are urgent to get the price.Please call us or tell us by email so that we will take your inquiry as priority.

Q3. How can we guarantee quality?

A:Material inspect before mass production, make sure stable material quality(material IV, impurity, color,moisture,etc) QC will make inspect during whole production, including every technical data from customer, make sure it's all higher standard than customer needs.

Q4.Can you make other sizes and packaging for this product?

A:Yes, we can produce other sizes of products according to your requirements, usually our quotation includes ordinary packaging.If you need your own parcel, we can discuss in advance in order to get the solution.

Q5. Can we place a small order?

A:Yes, we accept trial small order, LCL shipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews