OEM New Technology Pet Strap Extruding Line 350KG/H High Capacity Making High Tension PET Strapping

Application of PET strap

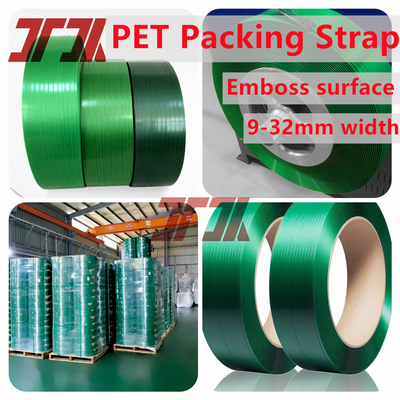

PET packing strap is widely used, replaced for steel strap for packing application internationally, because of its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc.

It is used in banding glass, steel, stone, construction material, chemical fiber, paper making, tobacco, agriculture… etc.

Technical parameters of PET belt 3output production line

| Raw material |

PET tackifier material or PET recycled material |

| Width of final product |

9-32mm |

| thickness of final product |

0.4-1.2mm |

| Max Capacity |

300-330kg/h |

| Manpower |

1-2 persons/shift |

| Machine Dimension |

55*2*8m |

| BRANDS |

| Gearbox: |

GUOMAO |

| Contactor: |

Schneider |

| Temperature controller |

Fotek |

| Inverter |

INVT |

Each parts of PET strap production line

Dehumidifier Crystallization:

The raw material is dried by the dehumidifier, with a dew point below 40°C ensuring material humidity remains under 40 PPM for effective condensation polymerization.

The enclosed and circular conveyor system prevents air exposure, optimizing drying efficiency.

Extruder Screw:

A specially designed extruder screw for PET production enhances material separation and mixing. Automatic material feeding ensures smooth and stable PET strap production.

Mould:

The extrusion die and mould are precision-engineered for stable production and smooth strap surfaces.

An improved screen changer allows for non-stop operation with zero material leakage.

Cooling:

The water tank cools the PET straps, while consistent water temperature enhances molecular tension strength.

Heating:

A heating oven performs thermal annealing to eliminate band distortion caused by long-term storage.

Five Roll Wheels:

Larger haul-off rollers ensure superior product quality, while advanced rolling technology eliminates traditional issues like high gradient and bending deflection.

The embossing roller produces clear, even patterns.

Winding:

A dual-station automatic winder offers easy and efficient operation.

Our Commitment:

We provide turnkey solutions worldwide, supporting customers from installation to full production.

Our Workshop

FAQ

1. Are you trading company or manufacturer?

We are manufacturer, and also provide the business solution to all the friends.

2. Do you have quality certificate?

Yes we have CE, SGS etc.

3. What's the delivery time?

Around 40~50days, however, based on order.

4. What is your overseas service?

We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews