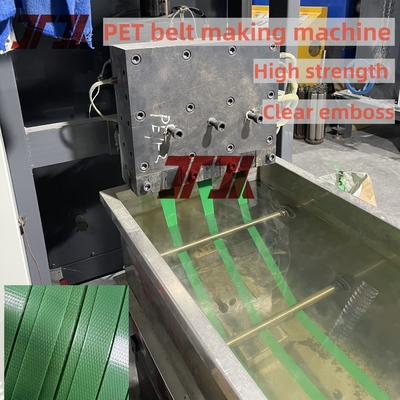

9-32mm Customized Pet Straps Double Output Making Machine With Automatic Winder And 350-850kg Strength

PET Straps 2output Production Line Machine List

| Item |

Quantity |

| 1. Lifting mixing drying system and screw feeding system |

1 set |

| 2.450 type dehumidifier and drying crystallization tank |

1 set |

| 3. single screw extruder |

1 set |

| 4. high-power screen changer |

1 set |

| 5. metering pump with independent speed regulation system |

1 set |

| 6. Special mould for PET strap band (90 2output) |

1 set |

| 7. Cooling water tank |

1 set |

| 8. The first five-roller tractor |

1 set |

| 9. Stretching oven |

1 set |

| 10. The second five-roller tractor |

1 set |

| 11. Embossing machine |

1 set |

| 12. The third five-roller tractor |

1 set |

| 13. Cooling sizing system |

1 set |

| 14. The fourth three-roller tractor |

1 set |

| 15. double station semi-automatic winding machine |

1 set |

Production description of PET strap

The PET packing strap production line represents a next-generation model of packing material machinery, incorporating advanced international technology. PET packing straps are the optimal replacement for traditional packing materials and have gained widespread acceptance in the global packaging industry. Today, PET packing straps are extensively utilized across various sectors, including paper, steel, chemical fiber, cotton, printing, wood, and more, making them a versatile and reliable solution for modern packaging needs.

PET Strap Making Production Line Function

1.No Separate Drying Required: PET raw materials do not require separate dry and water treatment processes. The system features automatic preheating and drying circulation, significantly reducing equipment investment and cutting production costs by 30%.

2.Cost-Effective Raw Materials: By using recycled bottle flakes as raw materials, production costs are greatly reduced, making it an economical and sustainable solution.

3.Versatile Production: The multi-purpose machine can produce PET straps in various specifications without the need to change the mold head, enhancing flexibility and efficiency.

4.High-Quality Output: The transparency of the products matches that of new polyester flakes, while the tensile strength and shock resistance meet international standards, ensuring superior performance.

5.Energy Efficiency: The production line is designed for low energy consumption while maintaining high production capacity, making it both eco-friendly and cost-effective.

6.User-Friendly Operation: The system is easy to operate, requiring minimal manpower. On average, only two personnel are needed to manage one production line, reducing labor costs.

ABOUT OUR COMPANY

Jiatuo Machinery Co., Ltd. is a professional manufacturer for kinds of plastic machines, such as PP & PET plastic strap extrusion line, PP strap, PET strap and plastic process auxiliary machines, etc. which have nearly 30years experience.

The target of Jiatuo Machinery Co., Ltd. is to offer the best quality machines to the customers from all over the world. With the advanced technology, experienced engineers and skilled workers, we have the capability to manufacture specific machines according to customer's requirement.

Excellent quality and professional service is the promise made by Jiatuo Machinery Co., Ltd. to new and old friends.

We are looking forward to establish good cooperation relationship with you on the basis of mutual benefits.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews