PET plastic strapping equipment PET plastic steel strapping production line for 100% bottle flake production

Product Description of pet strap manufacturing machine:

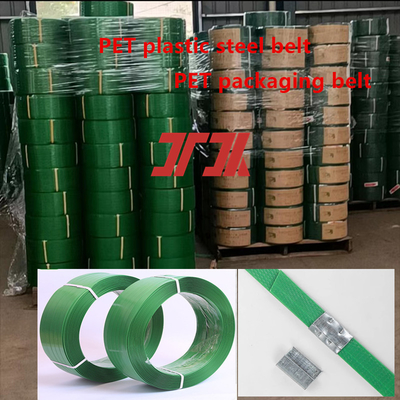

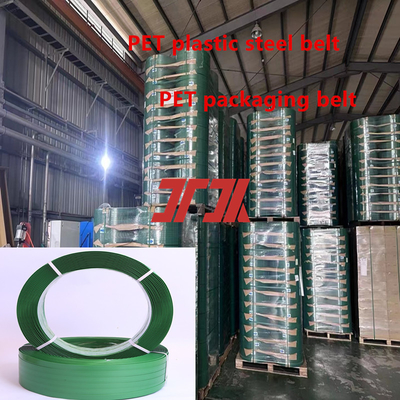

PET strapping machine is an industrial equipment used to make polyethylene terephthalate (PET) strapping, which is widely used for packaging and strapping in various industries such as logistics, construction, steel, aluminum, chemical fiber, cotton spinning, etc.

PET strapping is a strong and environmentally friendly alternative to steel strapping and PP strapping, with its high tensile strength, flexibility and recyclability as its advantages.

Raw materials: 100% bottle flakes & PET crushed materials

Technical parameter of PET strap double output extrusion line

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

100% Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Winding machine |

Automatic winding/ Semi-automatic winding |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

PET Packaging Belt Production Line Process Flow

Embark on a journey through our meticulous production process: Loading → Mixing raw materials → Pre-drying → Vacuum dehumidification → Extrusion → Cooling and forming → Preheating → Primary stretching → Secondary stretching → Embossing → Tempering → Cooling → Finished product winding. Each step is designed to ensure the highest quality output.

Advantages of PET Plastic Steel Belt Equipment:

Economical and Efficient: Our equipment is engineered for longevity and minimal maintenance, delivering an unparalleled degree of automation, making it the ultimate economical and efficient choice for packaging material production.

Unmatched Efficiency: High strength and durability guarantee seamless material handling, sustainable production, and minimal downtime, enhancing overall productivity.

Uncompromised Safety: Designed with a sturdy structure, our equipment ensures safe, reliable operations, significantly reducing the risk of belt failure for peace of mind.

Energy Saving: Pioneer energy efficiency and environmental protection with our equipment, which promises high output paired with low power consumption, reinforcing your commitment to sustainability.

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A:shenzhen, China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20-23T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews