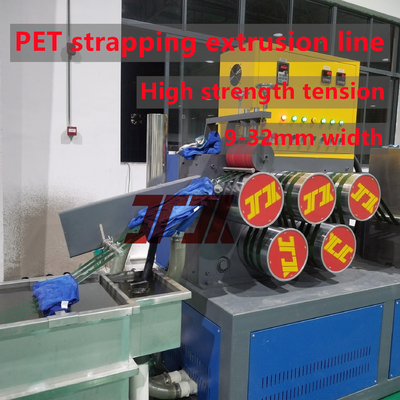

9-32mm Polyester Pet Plastic Steel Belt Extrusion Line with Double Cylinder Changer

Technical Parameters of PET belt making machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Single/double cylinder (No-stop changer)

|

|

|

9-32mm adjustable(width error within 0.3mm)

|

Main part of PET strap extrusion production Line

1. Drying crystallization system

2. Mixing system

3. Single screw Extrusion head (size can be customized accroding to capacity needing)

4.screen changer(single/double cliyner), High temperature melt pump,

5. Water cooling tank (3-4m in length, rapidly lower temperature)

6. first 5-roller traction

7. Strength oven

8. The first stretching machine

9. The second stretching machine

10. Embossing machine

11. Shaping oven (part to Avoid cracking of the strap)

12. wind system (Reduce temperature of strap)

13. Double-position winding machine (PLC controlled)

PET Strap Production Line Process

Material loading → Mixing of raw materials → Pre-drying of raw materials → Vacuum dehumidification of raw materials → Melting of raw materials, metering and extrusion → Cooling and forming of preforms (preforms) → Pre-heating of oven → Once stretching → Second stretching → Embossing → Tempering of oven → Cooling of oven → Finished product rewinding

Advantages of PET belt production line

High capacity. According to the demand for production can be customized most suitable equipment program, for example, the output of 3 extrusion can reach 300-330kg / H

Using PLC control system, which makes the production of PET strap stable and high quality. The width and thickness of the products have small error. width error within 0.3mm, over country standard.

Customizable to meet specific requirements. For example: double embossing, body color, customized width and thickness, etc.

Energy saving and material saving. Save 20-30% of actual energy consumption which can reach high profit.

Easy to operate and maintain. Only 2 workers are needed to operate the machine, saving labor cost.

Why choose us

Comparing with the low price low quality machine, Please note our strong advantages:

1. Nearly 30 Years Experiences;

2. GermanTechnology;

3. High Efficiency Oven Heating and Annealing system;

4. PLC Controlled of whole line;

5. Fully Automatic No-Stop Screen Changer;

6. Easy to Operate, Stable Performance, Good Quality Straps, Low Production Cost;

7. Quicker Production Speed, high Output;

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews