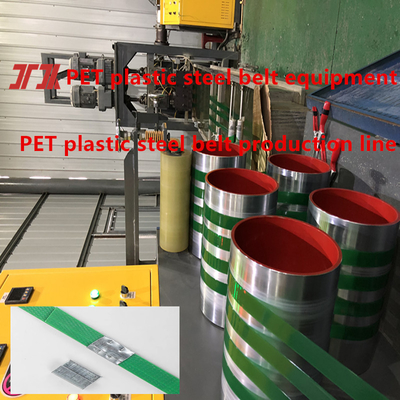

High-speed intelligent PET extruder PET packaging belt equipment PET plastic steel belt production line

Product Description of pet strap manufacturing machine:

PET strapping production line is a high-speed, intelligent and environmentally friendly plastic equipment with the following advantages:

1. Raw materials: PET plastic steel belt can use raw materials: bottle flakes or crushed materials or thickening granular materials

Bottle flakes: waste mineral water, Sprite, Coke and other bottle flakes as raw materials, which are crushed, cleaned and dried.

Crushed materials: finished PET plastic steel belt is crushed and screened, cleaned and dried;

Viscosity granular materials: PET crushed materials are processed, cleaned and thickened granular materials

Dehumidifier: The rotary honeycomb dehumidification and drying system is used to dry the raw materials. The dew point of -50ºC ensures that the moisture content of the raw materials is ≤50PPM, and also has the effect of solid phase polycondensation and viscosity increase.

PET belt, also known as plastic steel belt, is a new type of binding belt that is currently popular in the world to replace steel belts, and is widely used in steel, aluminum, chemical fiber, cotton, tobacco, paper, metal canning and other industries

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

100% Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Winding machine |

Automatic winding/ Semi-automatic winding |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20T |

Pre-drying and dehumidification part

Filter: Three-dimensional foldable large-area filter device, the unfolded area of the filter is 30 times larger than the traditional flat filter area; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.

pet strap production line

pet strapping band making machine

pet strapping band machine

pet strapping band making machine

PET packaging tape, also known as plastic steel tape, is a new type of binding tape that replaces steel tape. It is widely used in industries

such as cotton spinning, chemical fiber, metallurgy, casting, can making, refractory materials, ceramics, brick making, glass, paper making, furniture, tobacco, wood, electronics, etc.

The PET plastic steel belt production line is equipped with a special screw for the extruder,

which has good plasticization, strong friction ability and long service life.

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews