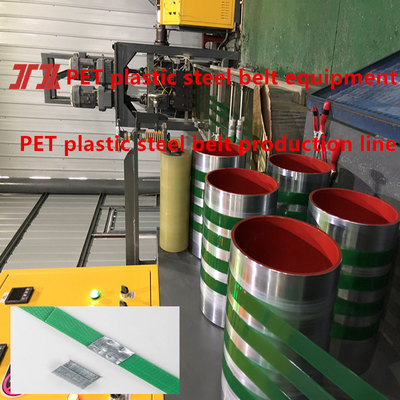

Manufacturers produce PET extruder PET packaging tape equipment for automatic winding machine

Product Description of pet strap manufacturing machine:

PET strapping production line equipment fully meets environmental protection requirements. PET plastic steel belt can be produced using 100% waste mineral water, Sprite, Coke and other bottle flakes as raw materials.

PET strapping production line equipment is equipped with PLC computer control system control, which is used for real-time memory control of melt temperature, pressure, extrusion speed, torque, traction, etc. to ensure that the product quality is the same every time.

The equipment is equipped with two sets of shaping oven systems, one stretch shaping, two shaping shaping, etc. The equipment consists of: stirring part, feeding part, drying part, dehumidification part, main machine part, cooling part, extension part, shaping part, small traction part, large traction part, embossing part, winding machine, etc.

PET plastic steel belt winding machine can be equipped with: Automatic winding machine or semi-automatic winding machine

Technical Parameters of pet strap manufacturing machine:

| Type |

PET Plastic Extrusion Machine |

| Strap Width |

9-32mm |

|

StrapThickness

|

0.6-1.2mm |

| Switchgear |

Schneider |

| Solid-state Relay |

Taiwan Fotek |

| Screw |

100*2900mm |

| Raw Material |

100% Recycled Bottle Flakes Material |

| Weight |

18000KG |

| Warranty |

1 Year |

| Winding Method |

Manual/Automatic |

| Cylinder |

Double Cylinder/Single Cylinder |

| Control System |

PLC Control System |

Pre-drying and dehumidification part

Using advanced technology, honeycomb system rotary dehumidification system, dust removal, oil removal, to achieve constant temperature and humidity, to ensure the strict dehydration requirements in the PET strapping production process.

pet strap production line

pet strapping band making machine

pet strapping band machine

pet strapping band making machine

PET packaging tape, also known as plastic steel tape, is a new type of binding tape that replaces steel tape. It is widely used in industries

such as cotton spinning, chemical fiber, metallurgy, casting, can making, refractory materials, ceramics, brick making, glass, paper making, furniture, tobacco, wood, electronics, etc.

The PET plastic steel belt production line is equipped with a special screw for the extruder,

which has good plasticization, strong friction ability and long service life.

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews