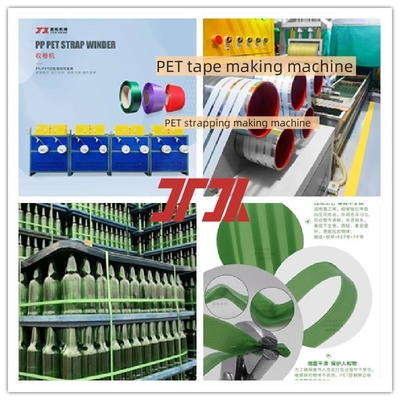

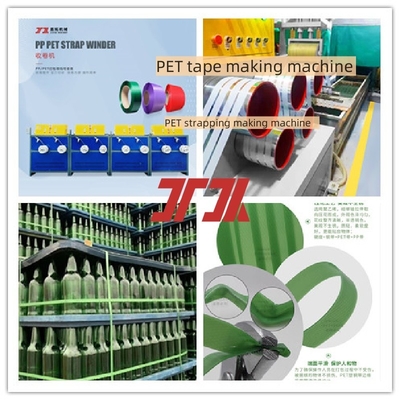

Plastic Machinery Single Screw PET Plastic Steel Belt Equipment PET Belt Making Machine with High Hardness Screw

Product Description:

PET strapping production line is a high-speed, intelligent, environmentally friendly plastic equipment, its advantages:

Raw materials:

PET plastic steel belt can use raw materials: 100% bottle flakes or crushed materials or thickening granular materials

1. Bottle flakes--- waste mineral water, Sprite, Coke and other bottle flakes as raw materials, after crushing, cleaning, drying materials.

2. Crushed materials---- finished PET plastic steel belt after crushing, screening, cleaning, drying raw materials;

3. Thickening granular materials----PET crushed materials after processing, cleaning, thickening granular materials

Features of PET plastic steel belt:

PET belt, also known as plastic steel belt, is a new type of strapping belt that is currently popular in the world to replace steel belt. It is widely used in steel, aluminum, chemical fiber, cotton spinning, tobacco, paper industry, metal can making and other industries.

Strong tensile strength: It has both the tensile strength of steel belt and the ductility to resist impact, which can ensure the transportation safety of your products.

Low elongation: The elongation is only one-sixth of that of polypropylene (PP) belt, and it can maintain tension for a long time.

Technical Parameters:

| Technical Parameter |

Description |

| Name |

PET strapping production line

|

| PET Strap Width |

9-32mm |

| Host Inverter |

55KW(INVT) |

| Final Product |

PET Packing Strap Belt |

| Strap Number |

2-8 Strap |

| Screw |

100*2900mm |

| Raw Material |

PET Bottle Flake Material, 100% Broken Material |

| Warranty |

1 Year |

| Switchgear |

Schneider |

| Strap Thickness |

0.6-1.2mm |

| Capacity |

300-350KG/H |

| Control System |

PLC control system |

Applications:

About the screw of PET equipment:

Extrusion scre---The extruder of the PET plastic steel belt production line adopts a PET special screw with a unique parameter design. The screw has a unique separation and mixing effect, which ensures the uniform plasticization of the raw materials. It has the advantages of large extrusion volume, good plasticization, high hardness, and high wear resistance.

Extrusion scre---The flow channel is extruded evenly, with high hardness, wear resistance and corrosion resistance, and long service life.

Services:

After-sales service

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews