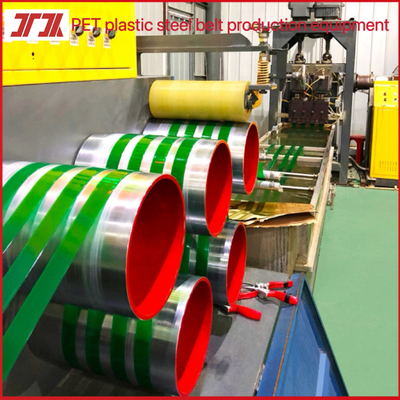

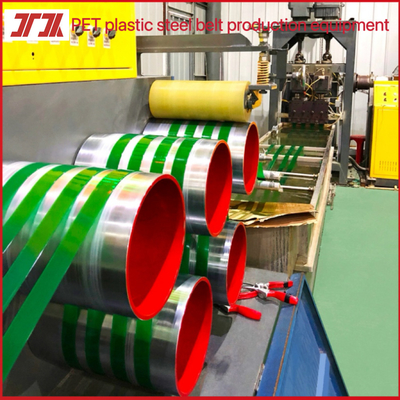

Packaging machinery 9-32mm PET extruder PET strapping production line for servo motor winding machine

PET plastic steel strapping tape has a wide range of uses and is suitable for most industrial packaging, such as brick packaging, steel, wood, stone, aluminum ingots, large cartons, etc., and has a very good packaging effect.

1) Tensile strength: strong tensile strength, with the same tensile strength as steel straps and ductility to resist impact, which can ensure the safety of product transportation.

2) Stretch rate: small elongation, which is only one-sixth of that of polypropylene straps, and can maintain tension for a long time.

3) High temperature resistance: strong temperature resistance, melting point is 260 degrees, and it will not deform when used below 120 degrees.

4) Anti-corrosion: good safety, no risk of steel straps rusting and contaminating the tied objects, and the color is bright and visible.

5) Affordable price: low manufacturing cost, affordable price, the length of 1 ton of PET strapping tape is equivalent to the length of 6 tons of steel straps of the same specification, and the unit price per meter is more than 40% lower than that of steel straps, which can reduce packaging costs.

Features of PET Strap Making Machine:

PET strapping production line is a high-speed, intelligent, environmentally friendly plastic equipment, its advantages:

1. Raw materials---- PET plastic steel belt can use raw materials: bottle flakes or crushed materials or thickening granular materials

2.Bottle flakes----waste mineral water, Sprite, Coke and other bottle flakes as raw materials, after crushing, cleaning, drying materials.

3.Crushed materials---- finished PET plastic steel belt after crushing, screening, cleaning, drying raw materials;

Thickening granular materials---- PET crushed materials after processing, cleaning, thickening granular materials

Technical Parameters of PET Strap Making Machine:

| Parameter |

Details |

| Product Name |

PET Strap Making Machine |

| Raw materials |

100% bottle flakes or crushed materials |

| Strap Thickness |

0.3-1.2mm |

| Strap Width |

9-32mm |

| Metering pump |

100CC |

|

Dehumidifier

|

1000-2000Air volume |

|

Gross weight

|

20kg/reel

|

|

Net weight

|

19kg/reel |

|

Screw

|

130mm

|

| Voltage |

380V 50HZ 3Phase(Customized) |

Applications of PET Strap Making Machine:

Our PET Plastic Steel Strap, a hot melt adhesive marvel, works seamlessly with various strapping tools, offering versatile bonding through electric heating, friction, and hot melt.

1. Handheld Strapping Machine

2. Pneumatic Strapping Machine

3. Manual Iron Buckle Strapping Machine

4. Automatic Strapping Machine

After-sales service:

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews