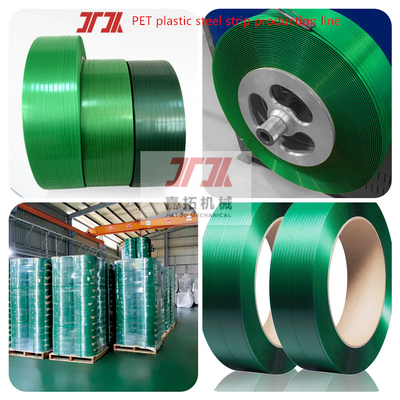

High-end Intelligent PET Plastic Steel Belt Production Line Pet Belt Equipment with Servo Winding Machine

Product Description of PET plastic steel belt equipment:

PET plastic steel strapping belt is produced by a new type of PET strapping machine using domestic advanced technology. PET plastic steel strapping belt purchases mineral water bottles, Sprite bottles, etc. as raw materials. At present, PET plastic steel strapping belt has been widely used in papermaking, steel, chemical fiber, cotton, printing, wood and other industries.

*Metering extrusion system------The metering extrusion system makes the flow channel extrusion more uniform, so that the width of the PET plastic steel belt remains consistent,50CC-100CC.

*Screen changer--------The three-dimensional foldable large-area filter device has an unfolded filter area that is 30 times larger than the traditional flat filter area; the filter mesh can reach 80 meshes, and the unique screen changing device greatly reduces the screen changing time and improves work efficiency.The filtration area can reach 3.5 square meters.

*Dehumidifier--------The rotary honeycomb dehumidification and drying system is used to dry the raw materials. The dew point of -50ºC ensures that the moisture content of the raw materials is ≤50PPM, and also has the effect of solid phase polycondensation and viscosity increase.1000-2000 dehumidification air volume.

*PLC control system--------The machine adopts PLC control, parameter setting, data and the feedback and alarm automation.

Technical Parameters of PET plastic steel belt equipment:

| Type |

PET Plastic Extrusion Machine |

| Materials |

PET raw material or 100% PET bottle flakes recycled |

| Product |

150-600kg/h |

| Paper tube size |

GUOMAO |

| Strap Width |

9-32mm |

| Paper core diameter |

Ø406*150mm |

| Power |

55KW |

| Strap Thickness |

0.6-1.2mm |

| Control System |

PLC Computer Touch Screen |

| Winding method |

Manual/automatic |

| Weight |

21T |

Applications of PET plastic steel belt equipment:

- no damage or contamination of packaged goods (corrosion-resistant)

- high shock absorption in case of impacts during transportation

- less pressure on edged of the package

- perfect and individual secured packages

- strap tension remains tight in cases where package may shrink during storage or transportation

- substitution of steel strapping by Polyester strapping allows the use of a strap with less breaking strength

- reduction of material costs (up to 50 %)

- less injury risks in case of strapping breakages

- easy and clean handling compared to steel strapping

Customization:

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews