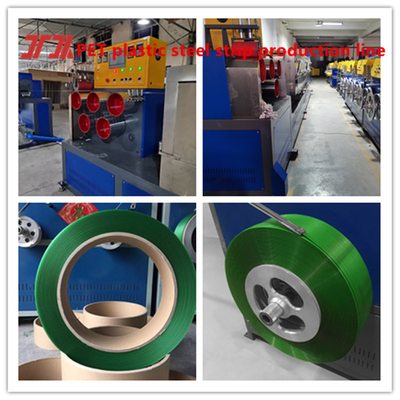

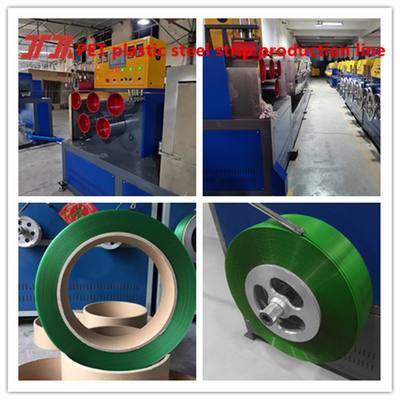

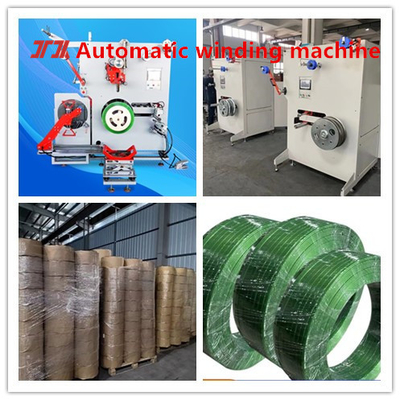

PET plastic steel belt production equipment PLC control system servo winding machine 200-600KG/H

Product Description:

The PET plastic steel belt production equipment is a high-speed intelligent extruder, high-speed inverter, and reducer that can maintain the accuracy of the production process while running. In addition, the PET plastic steel belt production equipment is equipped with a PLC control system, which can achieve seamless control and monitoring of the production process to ensure that the final product meets the required specifications.

1.Screw: Special twin screw extrusion technology and single screw extrusion technology can be choosing as per customer needs.

2.Material: Process 100% recycled/ PET bottle flakes

3.Control system: Even plasticization and stable extrusion with PLC automatic control for the full line.

4.Melt filter: with two pistons with air venting design and back flushing.

5.Number of strap:2,3,4,6,8. Width: 9mm-32mm,Thickness: 0.4mm-1.2mm

6.Workers: 2 -3 workers per shift, 12 hours/shift.

7.Our PET strap machine could meet over 4-5.5:1 stretching rate, and 140m/min speed extrusion.

Technical Parameters:

| Name |

PET Plastic Steel Belt Production Equipment |

| Strap number |

2-8 Strap |

| Raw material |

PET Bottle Flake Material, 100% Broken Material |

| Paper core diameter |

Ø406*150mm |

| Voltage |

380V/50HZ (customized) |

| Host inverter |

55KW(INVT) |

| Final product |

PET Packing Strap Belt |

| Control system |

PLC control system |

| Automation |

Automatic |

Applications:

1. Honeycomb rotary dehumidification dryer: 0ST-2000 1 set; it has strong dehumidification ability, and the finished PET plastic steel belt produced is not easy to crack, etc.

2. Oil removal filter: 1 set; it has strong decontamination ability, and the finished PET plastic steel belt produced is not easy to crack, etc.

3.Pre-drying tower: 5000L,:stirring belt drying, better dehumidification effect.

Support and Services:

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q1: What is the brand name of this PET Strap Making Machine?

A1: The brand name is PET plastic steel belt production equipment.

Q2: What is the model number of this machine?

A2: The model number is JTPET-100.

Q3: Where is this machine made?

A3: It is made in China.

Q4: Does this machine have any certification?

A4: Yes, it has IS CE certification.

Q5: What is the minimum order quantity for this machine?

A5: The minimum order quantity is 1 set. The price is negotiable and it is packaged with plastic film. The delivery time is 50-60 days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews