High-end pet strapping band making machine PLC control system Servo winding machine

Product Description of pet strapping band making machine:

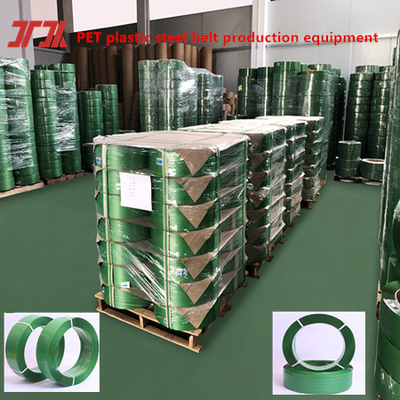

PET strapping production line is a high-speed, intelligent and environmentally friendly plastic equipment with the following advantages:

1. Raw materials: PET plastic steel belt can use raw materials: bottle flakes or crushed materials or thickening granular materials

Bottle flakes: waste mineral water, Sprite, Coke and other bottle flakes as raw materials, which are crushed, cleaned and dried.

Crushed materials: finished PET plastic steel belt is crushed and screened, cleaned and dried;

Viscosity granular materials: PET crushed materials are processed, cleaned and thickened granular materials

2.Screw:The extruder of the PET plastic steel belt production line adopts a PET special screw with a unique parameter design. The screw has a unique separation and mixing effect, which ensures the uniform plasticization of the raw materials. It has the advantages of large extrusion volume, good plasticization, high hardness, and high wear resistance.

Technical Parameters pet strapping band making machine:

| Model |

PET-2 |

PET-3 |

PET-4 |

PET-6 |

PET-8 |

| Raw materials |

Bottle flakes/crushed materials |

| Number of tapes |

2 |

3 |

4 |

6 |

8 |

| Width (mm) |

9-32 |

| Width (mm) |

0.4-1.2 |

| Maximum line speed(m/min) |

≧150 |

≧150 |

≧150 |

≧150 |

≧150 |

| PLC control system |

PLC |

PLC |

PLC |

PLC |

PLC |

| Screw Model |

90 |

100 |

125 |

150 |

180 |

| Reducer model |

200 |

250 |

280 |

315 |

350 |

| Dryer tank |

3000L |

4000L |

5000L |

6000L |

6000L |

| Dehumidifier |

1000 |

1000 |

2000 |

3000 |

3500 |

| Metering Pumps |

100CC |

100CC |

100CC |

100CC |

100CC |

| Screen Changer |

Single cylinder |

| Production capacity /24 H |

5-6T |

7-8T |

10-12T |

12-15T |

18-20TT |

Features of pet strapping band making machine:

1. Double position winder: 2-3 sets

2. Paper core specification:¢ 406*150mm

3. Torque motor: 10 torsion meters

4. specification: 9-32mm

5. Dimension of thread return shaft: ¢ 32*150mm (imported from Taiwan)

Features:

The unique tooth return shaft is adopted to make the packing belt orderly arranged without superposition and horn shape, so that the packing belt can maintain good straightness, which is more suitable for the full-automatic packing machine to ensure that the full-automatic equipment can deliver the belt in place without dropping the belt.

Applications:

Our PET plastic steel belt equipment provides comprehensive technical support and services. We have an experienced technical team that can quickly provide a variety of services, including:

Pre-sales:

1. Layout of PET plastic steel belt equipment.

2. Analysis of finished product manufacturing costs of PET plastic steel belt equipment.

3. Analysis of raw materials used in PET plastic steel belt equipment.

After-sales service:

1. Waterway diagram, circuit diagram, pipeline connection drawings, etc. of PET plastic steel belt equipment.

2. Installation, commissioning and training of PET plastic steel belt equipment.

3. Maintenance service of PET plastic steel belt equipment.

4. Regular maintenance and repair

5. Fault diagnosis

6. Software update and upgrade

7. Spare parts and accessories

8. Training and technical consultation

FAQ:

Q: What is the voltage of the PET plastic steel belt equipment?

A: 380V/50HZ, three-phase (customization supported)

Q: What is the extrusion capacity of the PET plastic steel belt equipment?

A: Different models have different extrusion capacities, ranging from 150-600KG/H

Q: Where does the PET plastic steel belt equipment come from?

A: China.

Q: What are the certifications for PET plastic steel belt equipment?

A: ISO CEO certification.

Q: What is the minimum order quantity for PET plastic steel belt equipment?

A: 1 set

Q: What is the weight of the PET plastic steel belt equipment?

20T, 40GP container * 3PCS

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews